Struggling to understand the production process for seamless steel tubes? If you don’t understand how the tubes are made, you could end up buying materials that aren’t the best quality for your application. Learn how these tubes are made, because it’s critical to get a tubing material that will give you the performance and durability you need.

How Are Seamless Steel Tubes Made?

We are often asked about the process of making seamless steel tubes. It’s a very precise and intricate trip from raw material to finished product.

seamless steel tubes are made using high-quality steel billets. The process creates a strong, resilient material that can be used in many areas.

There are several ways to accomplish this, including heating, piercing, and finishing to create the tube. The key is to create a rolling process that doesn’t allow any internal or external welds to form. Wielding can weaken and damage the tube, so any kind of seam in the steel will be a weak point. To create a seamless tube, the steel billet is heated and pierced to create a solid tube—making it the most advanced type of steel tube you can buy.

Explore seamless tube basics and learn about the piercing process.

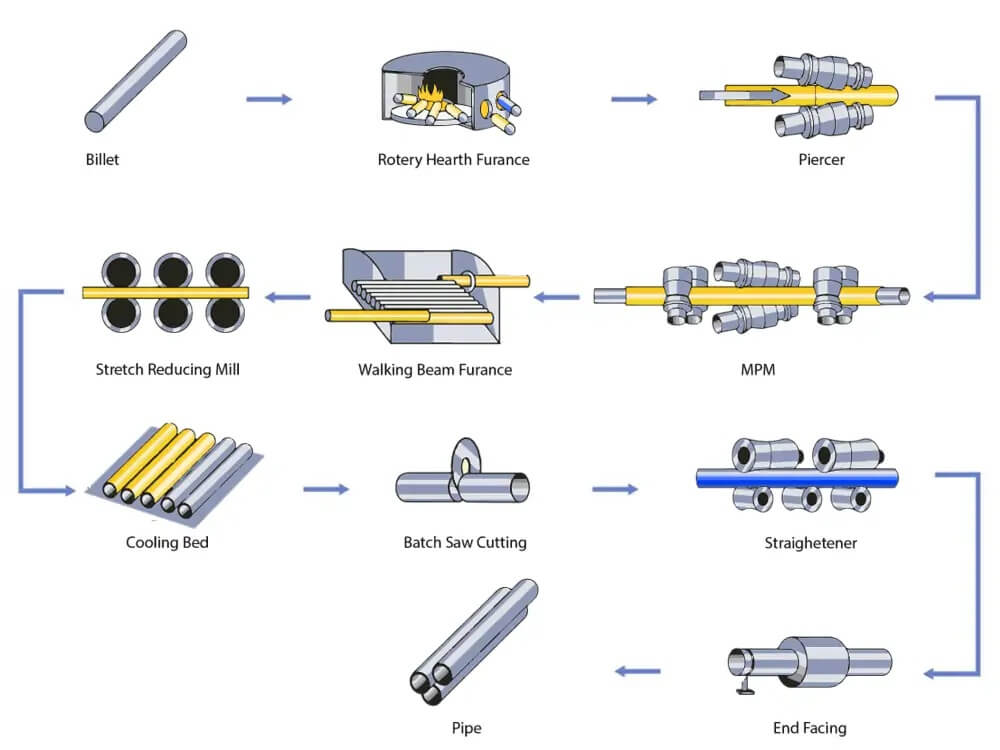

Key Steps in the Seamless Steel Tube Manufacturing Process

1.Material Selection

High-quality steel billets are meticulously chosen for their remarkable strength and purity. Rigorous quality inspections are performed to identify and eliminate any minute impurities, ensuring that the selected material aligns with strict industry standards.

Learn about steel billet selection and quality standards for billets.

2.Heating

Following selection, the steel billets undergo preheating within a specialized furnace, with temperatures reaching approximately 1,300°C (2,370°F). This crucial heating process renders the billets malleable, setting the stage for subsequent precise and meticulous processing essential for achieving the desired properties in the final tube product.

Discover preheating techniques and furnace types used in tube manufacturing.

3.Piercing

Upon completion of the preheating phase, the heated steel billets enter the next phase within the production journey: the rotary piercing mill. Employing this innovative technology, a hollow center is wrought within the billet, consequently forming the initial tubular blank. The piercing approach promotes homogeneous wall thickness and serves to eliminate any potential defects present within the billet material.

Read about rotary piercing technology and importance of defect-free piercing.

4. Rolling

- Hot Rolling: The hollow tube blank undergoes hot rolling processes, passing through mills to refine its dimensions and shape.

- Cold Drawing: In this phase, tubes are pulled through dies at room temperature, a cold drawing process which enhances dimensional accuracy and imparts increased strength.

Explore hot rolling benefits and cold drawing techniques.

5. Sizing and Cooling

Following the rolling and drawing phases, the tube proceeds to sizing, during which its diameter is adjusted precisely to align with specific dimensional requirements. Subsequent to this process, the tube is then effectively cooled using water or air, preserving its structural integrity and mechanical properties as it enters the concluding production stages.

Learn about sizing processes and cooling methods.

6. Straightening

Upon completion of the cooling stage, the tube undergoes straightening procedures to eliminate any potential twists or warps arising during manufacturing. This critical phase ensures the uniformity of the final product while affirming its alignment with defined dimensional tolerances.

Read about straightening techniques and why straightening is critical.

7. Heat Treatment

Multifaceted heat treatments, including the process of annealing, are implemented to enhance the mechanical properties of the tube. This treatment augments its strength, ductility, and resistance to stress, contributing to the optimized performance characteristics of the final product.

Discover heat treatment benefits and annealing process explained.

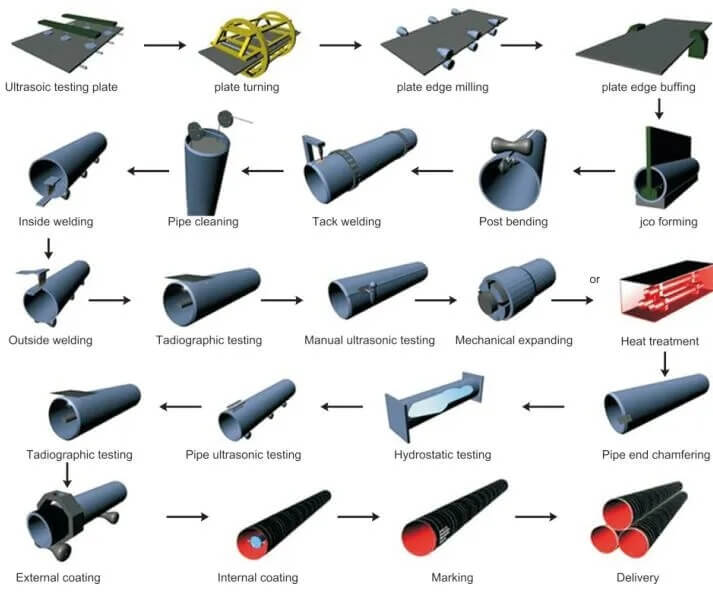

8. Surface Finishing

To achieve exceptional longevity and aesthetic appeal, tubes undergo rigorous cleaning and finishing procedures, including passivation and polishing, designed to bolster corrosion resistance and elevate their visual appeal.

Learn about passivation and surface finishing methods.

9. Inspection and Testing

Culminating in the production process is the seamless integration of exhaustive quality control measures, encompassing comprehensive visual inspections, precision dimensional measurements, and vital non-destructive testing (NDT) applications such as ultrasonic testing, which collectively verify the integrity and defect-free status of the manufactured tubes.

Read about NDT methods and quality control standards.

10. Final Packaging

The manufacturing process culminates with meticulous final packaging and labeling efforts specifically tailored to facilitate the safe transportation and enduring protection of the tubes, ensuring they remain easily identifiable and strategically shielded from potential harm both during shipment and upon arrival.

Explore packaging methods and importance of labeling.

Why Seamless Steel Tubes Are Superior

Seamless steel tubes possess several advantages over their welded counterparts:

- Uniform Strength: The absence of welds prevents the formation of weak points, endorsing seamless tubes for applications in high-pressure environments.

- Dimensional Accuracy: The implementation of hot rolling and cold drawing techniques guarantees consistent dimensions and exceptional surface finishes for seamless tubes.

- Versatility: Utilizing specialized alloys, including stainless steel, enables the production of seamless tubes with superb corrosion resistance and the capacity to withstand diverse environmental conditions.

Compare seamless and welded tubes and benefits of stainless steel.

Conclusion

The seamless steel tube manufacturing process combines advanced methods like rotary piercing, hot rolling, and cold drawing to create high-strength, weld-free tubes. These tubes are essential for applications in industries such as oil and gas, automotive, aerospace, and construction.

For premium seamless steel tubes, visit honingpipe.com or contact us at sales@cnsteelsupplier.com.