Struggling to find the right tube for high-precision applications? Understanding seamless steel honed tubes, their features, and benefits can help you make informed choices and avoid costly mistakes.

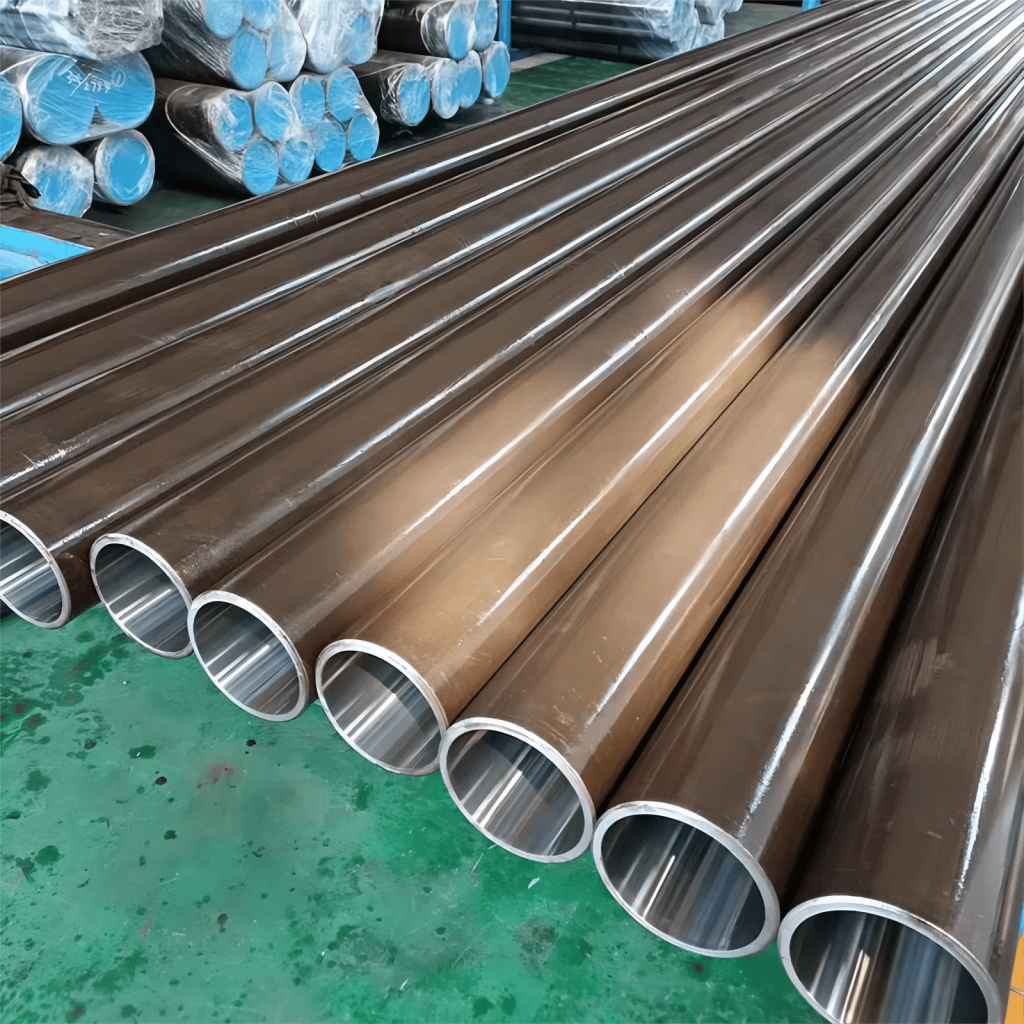

A seamless steel honed tube is a high-precision pipe with a smooth interior surface, essential for hydraulic systems and other demanding applications. Manufactured through processes like cold drawing and honing, these tubes offer superior dimensional accuracy and durability. They are extensively used in hydraulic cylinders, industrial machinery, and automotive components.

Delve deeper into seamless steel honed tubes to understand their key features, differences from other materials, and why they are indispensable in engineering applications.

What Is a Seamless Steel Honed Tube?

Struggling to find the right tube for high-precision applications? Understanding seamless steel honed tubes, their features, and benefits can help you make informed choices and avoid costly mistakes.

A seamless steel honed tube is a high-precision pipe with a smooth interior surface, essential for hydraulic systems and other demanding applications. Manufactured through processes like cold drawing and honing, these tubes offer superior dimensional accuracy and durability. They are extensively used in hydraulic cylinders, industrial machinery, and automotive components.

Delve deeper into seamless steel honed tubes to understand their key features, differences from other materials, and why they are indispensable in engineering applications.

What Is a Seamless Steel Tube Used For?

Are you wondering where you might use a seamless steel tube? The applications are vast. Use a seamless steel tube for:

- Hydraulic Systems, as it is a critical component in hydraulic cylinders for construction machinery and industrial machinery.

- Automotive Manufacturing, as it is used for precision parts like the drive shaft and suspension systems.

- Industrial Equipment, as it is used in high-pressure applications where structural integrity is required for the equipment.

Seamless steel tubes are designed to handle high pressures and maintain their dimensional stability. (Explore applications) (Find seamless honed tube suppliers)

What Is the Difference Between Seamless Steel and Stainless Steel?

Are you confused about whether to choose seamless steel or stainless steel? You need to understand that these are two different materials. Here are the differences:

- Seamless Steel: This refers to the manufacturing process. Seamless tubes are made without welds to provide smooth, uniform strength, and endurance.

- Stainless Steel: This refers to the material. Stainless steel offers excellent corrosion resistance and strength but at a higher price.

You can also combine them to make seamless stainless steel tubes for your unique application. (Explore seamless vs. stainless steel) (Compare seamless steel and stainless steel options)

How Does the Honing Process Improve Hydraulic Cylinder Tubes?

Are you experiencing trouble with your hydraulic systems? The honing process can make a massive difference in the quality of your tube.

Using the honing process helps improve:

- Surface Finish: This reduces the friction and wear, preventing gaps and further enhancing the tubing for a smoother ride.

- Geometric Accuracy: This ensures that the internal dimensions are the right size, which is crucial for the performance of your hydraulic system.

By doing these, you’ll improve efficiency, extend the life of your system, and enhance the performance of your individual parts. (Learn about honing benefits) (Explore hydraulic cylinder tube options)

What Are the Advantages of Seamless Steel Honed Tubes?

Looking for durable and high-performance tubing? Seamless honed tubes offer unmatched benefits.

- Enhanced Durability: Tubes manufactured through the honing process are more durable and resistant to wear and fatigue due to the removal of imperfections and stresses.

- Reduced Friction: The honed inner surface reduces friction and energy loss within the hydraulic system, ultimately leading to higher efficiency and lower operational expenses.

- Customization Options: The tubes come in a variety of sizes and materials, allowing for customization to suit the specific requirements of different applications.

Manufacturers that specialize in these products adhere to quality standards such as ISO 9001 and provide certifications for chemical and mechanical properties in line with industry standards. (Find quality standards) (Discover honed tube advantages)

What Are the Typical Chemical and Mechanical Properties of ST52 Honed Tubes?

Wondering why ST52 is widely favored for honed tubes? Its properties make it a standout choice for demanding applications.

- High Strength: ST52 tubes exhibit excellent tensile and yield strength, making them ideal for use in heavy-duty applications across various industries.

- Good Weldability: The material’s ability to be welded is a valuable attribute, facilitating customization and adaptability for specific application requirements.

- Low Carbon Content: The low carbon content of ST52 honed tubes provides ductility and enhances toughness, ensuring they can withstand demanding conditions.

ST52 honed tubes adhere to international standards, ensuring consistent and reliable performance in hydraulic systems. Moreover, manufacturers offer detailed material specifications and mechanical property guides for further reference. (ST52 properties guide) (Material specifications)

Conclusion

Seamless steel honed tubes are indispensable for high-performance hydraulic systems, offering superior durability, precision, and efficiency. Their applications span construction, automotive, and industrial sectors. With customizable options and adherence to stringent quality standards, these tubes are a versatile choice for engineers and manufacturers worldwide. (Find seamless honed tubes)

(Explore honed tube suppliers near you)