Selecting the appropriate hydraulic cylinder port size is critical for maximizing system performance. Miscalculating the port size can result in flow constriction, pressure imbalances, and decreased efficiency.

Sizing a hydraulic cylinder port requires consideration of flow rate, pressure demands, and bore size to ensure smooth operation and avoid flow restrictions within the hydraulic system.

Exploring these considerations, we will delve deeper into the process of accurately sizing ports, cylinders, and other components to ensure optimal performance of your hydraulic system.

What Is the Size of a Cylinder Port?

Problem: Choosing an improper port size can lead to inefficient hydraulic systems, resulting in suboptimal performance and increased wear.

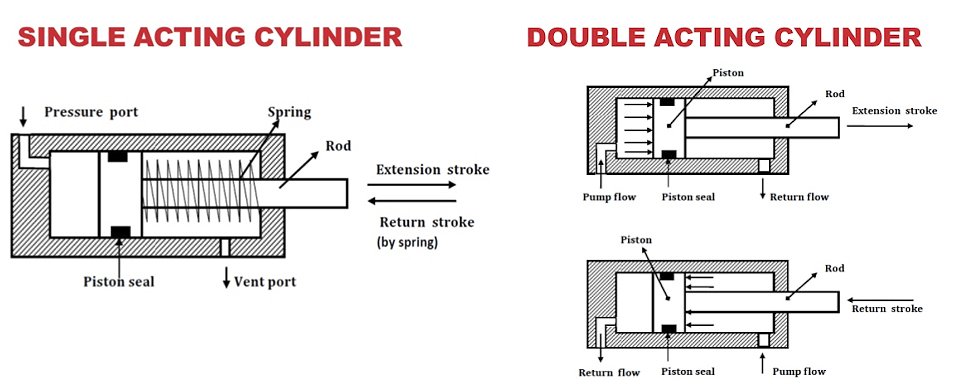

Agitate: If the port is too small, the flow of fluid will be restricted, leading to increased pressure and greater energy consumption. Conversely, if the port size is too large, pressure drops may occur, diminishing system efficiency.

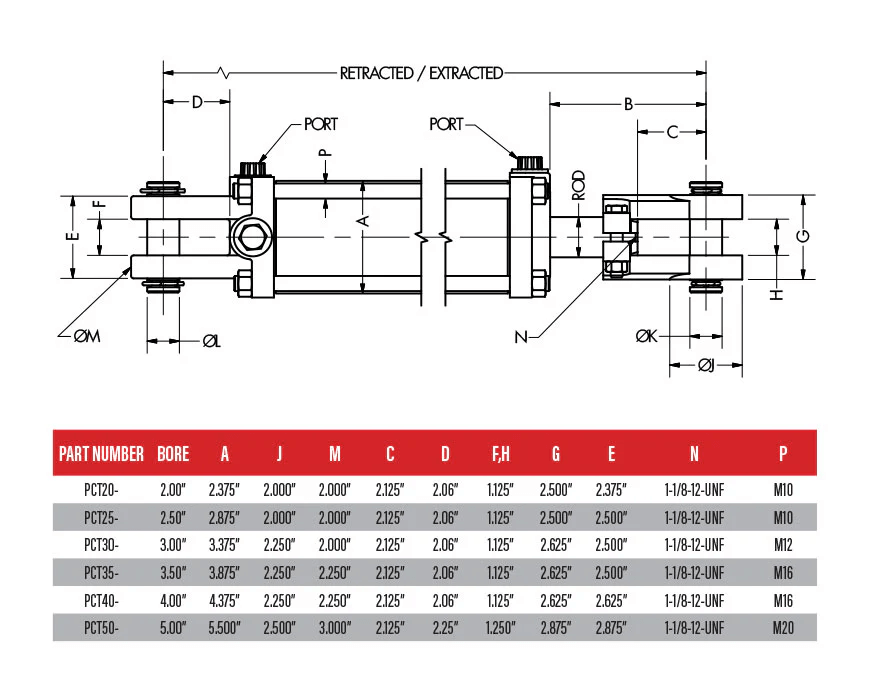

Solution: The size of a cylinder port should be based on the system’s flow rate and pressure. Common port sizes for hydraulic cylinders typically range from 1/4" to 1/2". Refer to a hydraulic cylinder sizing chart and manufacturer specifications to select the correct port size based on bore diameter and stroke length.

External Links for further reading:

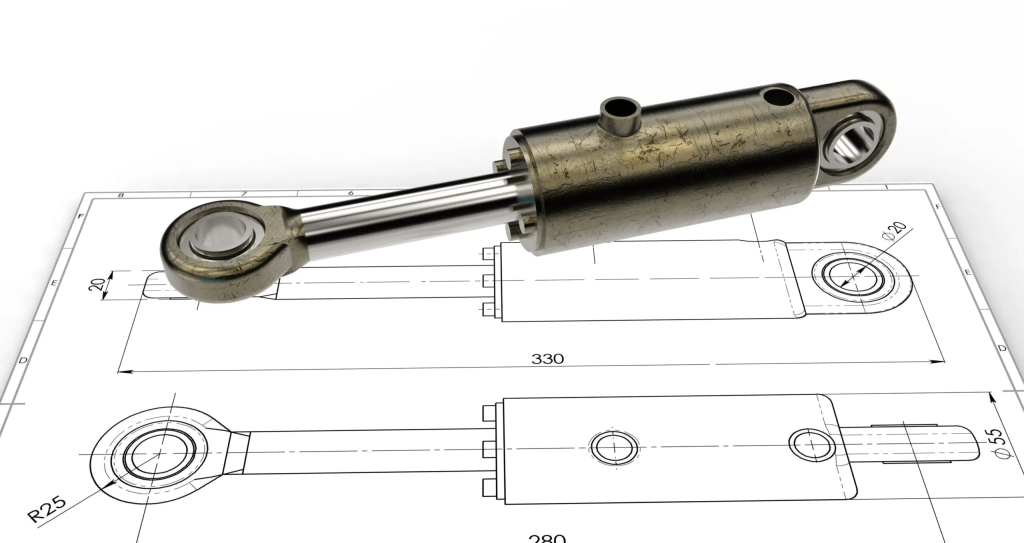

How Do You Measure Hydraulic Cylinder Length?

Problem: Accurate cylinder length measurements are fundamental to ensure compatibility within a hydraulic system.

Agitate: Inaccurate measurements can lead to inappropriate cylinder fit, resulting in operational issues such as misalignment and diminished performance.

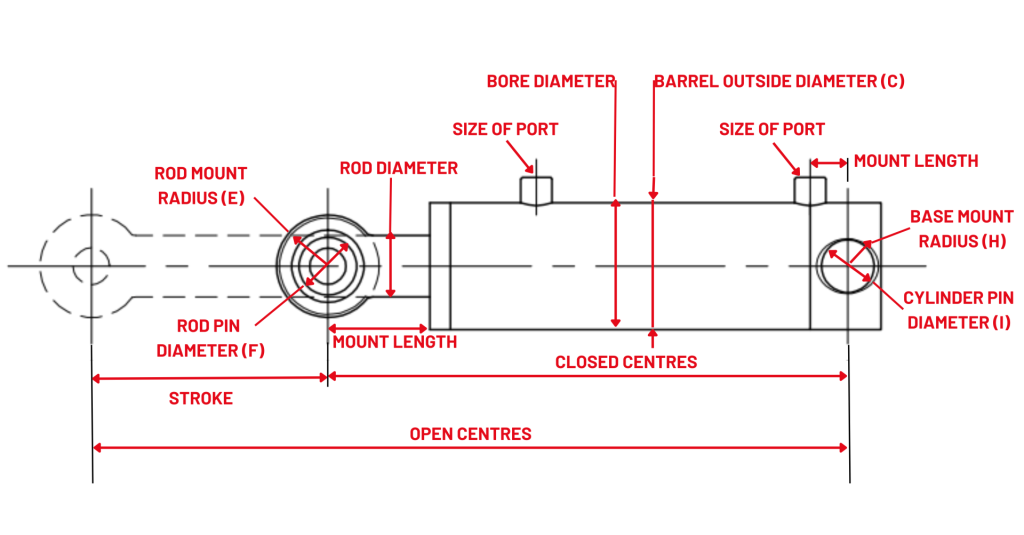

Solution: To measure the length of a hydraulic cylinder, determine the distance from the center of the mounting pin at one end to the center of the pin at the other end when the cylinder is fully extended. Additionally, factor in the bore size and stroke length. Utilize a Hydraulic Cylinder Size Chart PDF to compare specifications and identify the suitable cylinder for your requirements.

Snippet: To measure hydraulic cylinder length, evaluate the distance from one pin center to the other when fully extended, considering bore size and stroke length.

External Links for further reading:

How Do You Calculate the Size of a Hydraulic Cylinder?

Problem: Failure to calculate the appropriate cylinder size may lead to system underperformance or potential mechanical issues.

Agitate: Miscalculating the size of a hydraulic cylinder can result in insufficient power or overstressed components, ultimately increasing the costs associated with maintenance and downtime.

Solution: Calculate the size of a hydraulic cylinder using the formula:

Force (lbs) = Pressure (PSI) x Area (sq in) , with the bore size determining the area. Additionally, utilizing tools such as a Hydraulic Cylinder Size Calculator can simplify the process. Checking the Hydraulic Cylinder Bore Size Chart ensures the correct bore size is selected for the targeted force output.

Snippet: The size of a hydraulic cylinder is determined by multiplying system pressure by bore area, guaranteeing the required force for the intended application.

External Links for further reading:

How Do You Measure a Hydraulic Cylinder for Seals?

Problem: Inaccurate seal installation on a hydraulic cylinder may result in leakage and reduced operational efficiency.

Agitate: Without precise measurements, inappropriate seals may lead to improper fit, resulting in fluid leakage and potentially shortening the lifespan of hydraulic components.

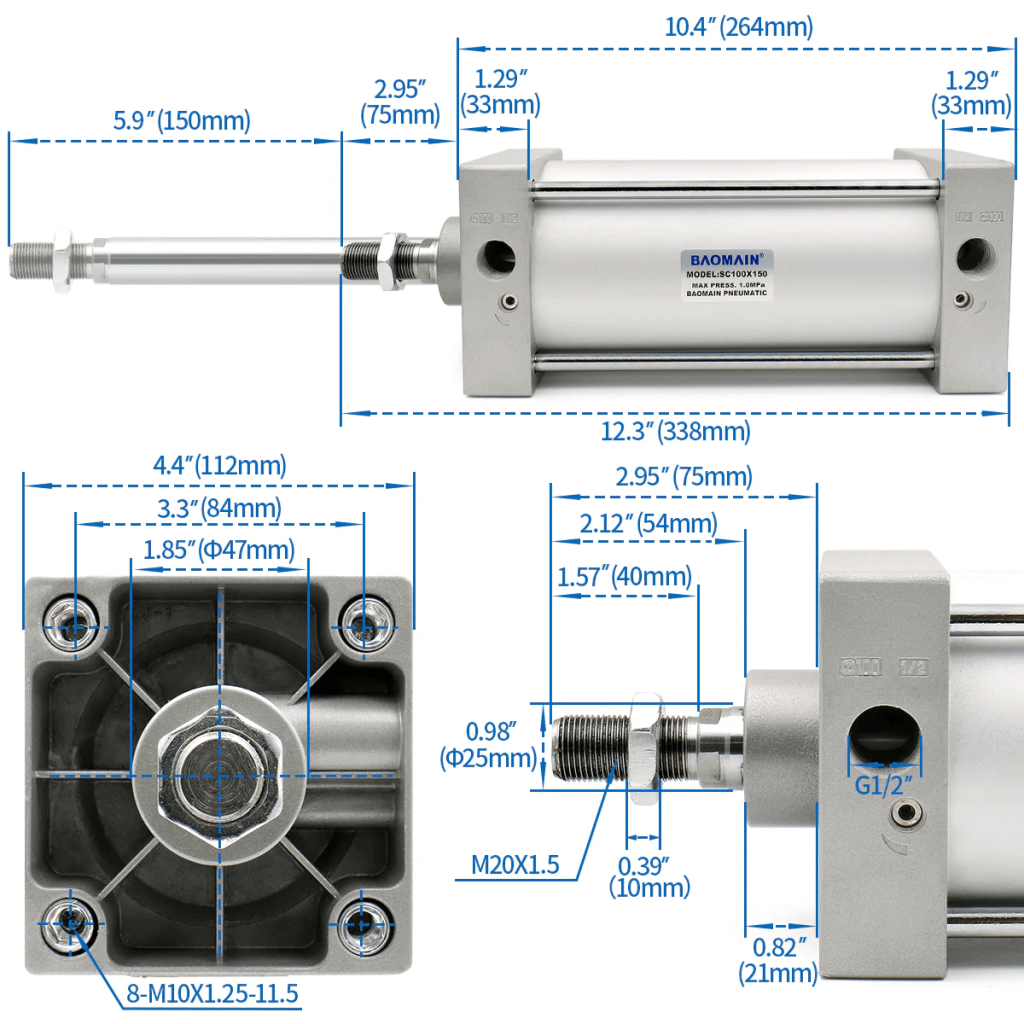

Solution: To measure a hydraulic cylinder for seals, employ calipers to measure the rod, bore, and groove diameters. Additionally, verify the cylinder’s stroke length. Many manufacturers provide various tools, such as Hydraulic Cylinder Stroke Length Calculators or measurement guides, to assist in obtaining accurate measurements.

Snippet: Measuring a hydraulic cylinder for seals involves utilizing calipers to measure the rod, bore, and groove diameters, as well as verifying the stroke length for accuracy.

External Links for further reading:

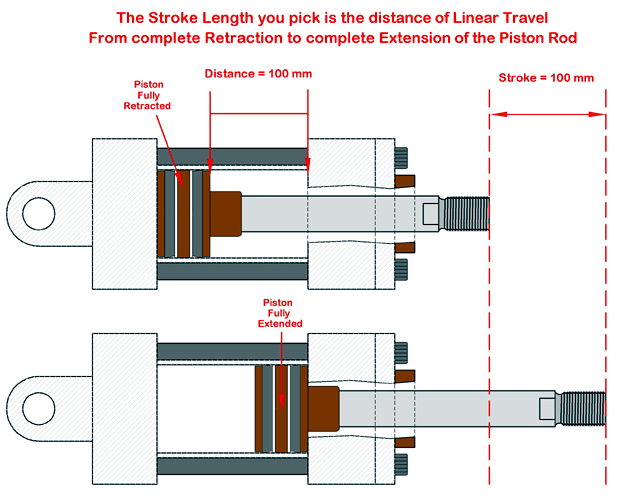

How Do You Calculate Hydraulic Cylinder Stroke Length?

Problem: Knowing the exact stroke length of your hydraulic cylinder is critical for ensuring the proper movement and function of your machinery.

Agitate: Inaccurate stroke length calculations can cause inefficiencies and limit the movement of the cylinder, affecting the overall performance of the system.

Solution: To calculate stroke length, measure the difference between the fully extended and fully retracted positions of the hydraulic cylinder. Reference a Hydraulic Cylinder Stroke Length Chart to ensure the correct stroke for your application.

Snippet:

Hydraulic cylinder stroke length is calculated by measuring the difference between the fully extended and fully retracted positions of the cylinder.

External Links for further reading:

Conclusion:

Correctly sizing and measuring hydraulic components like ports, cylinders, and stroke lengths is crucial for maintaining an efficient and reliable hydraulic system. By following these calculations and using the available tools, you can optimize your hydraulic machinery for better performance and durability.