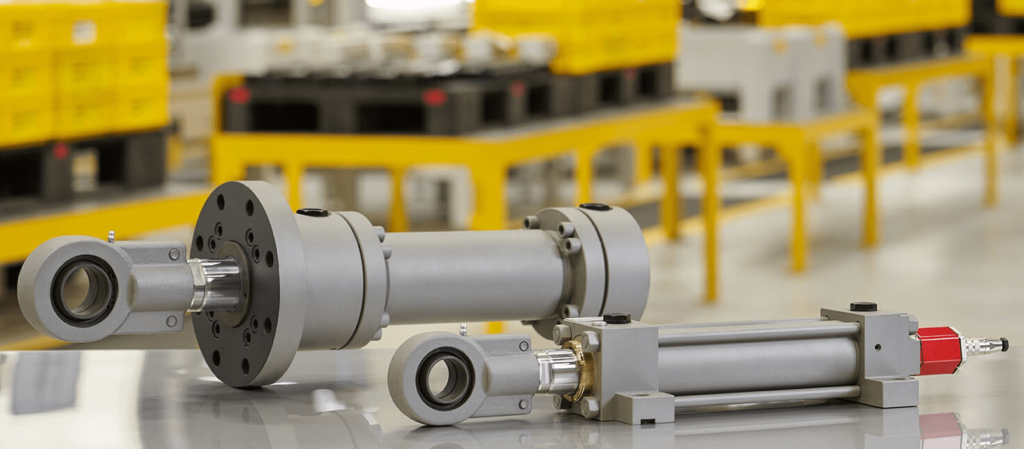

Industrial honed tubes are essential components in hydraulic and pneumatic systems, providing the precision and strength required across multiple industries. Their engineered design enhances the efficiency and durability of machinery in construction, manufacturing, and beyond.

With smooth internal surfaces that reduce friction, honed tubes play a key role in hydraulic cylinders, pneumatic systems, and various industrial applications. Their precision and durability contribute to machinery longevity and operational efficiency under high pressure.

Learn about applications of honed tubes in industrial systems.

Discover nearby suppliers of industrial honed tubes.

To fully understand the importance of honed tubes, let’s explore their diverse applications across industries and their key benefits.

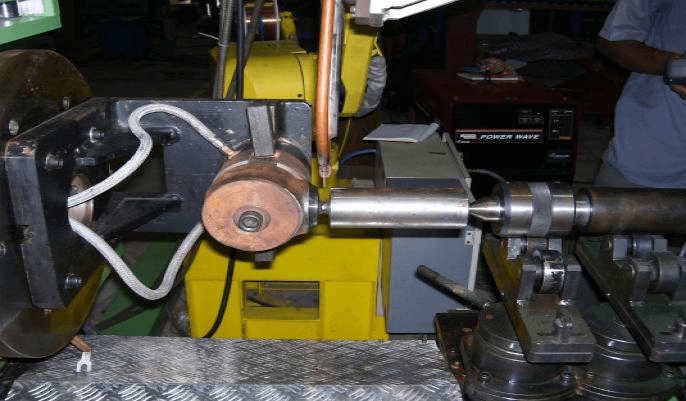

Uses of Industrial Honed Tubes

- Hydraulic Cylinders:

Honed tubes are essential for hydraulic cylinders, minimizing friction and ensuring smooth fluid flow in systems used in construction, agriculture, and manufacturing equipment. Their precision ensures enhanced performance and prolongs the operational life of the machinery. Learn more about honed tubes in hydraulic systems.

Discover options for hydraulic cylinder tubing.

- Pneumatic Systems:

In pneumatic applications, honed tubes support reliable motion control by delivering effective sealing, ensuring smooth operation powered by compressed air. They are integral to material handling and automation systems where stability is essential. Explore honed tubes for pneumatic applications.

Find suppliers for pneumatic cylinder components.

- Automotive Components:

Honed tubes enhance stability and performance in automotive components, including shock absorbers and steering systems, where precise motion and durability are critical. Learn more about automotive uses for honed tubes.

Discover suppliers of chrome-plated honed tubes.

- Industrial Machinery:

Honed tubes are crucial for ensuring precise and consistent movement in industrial machinery, such as printing presses and injection molding machines, vital for high-performance applications. Explore the use of honed tubes in industrial machinery.

Discover industrial tubing for manufacturing applications.

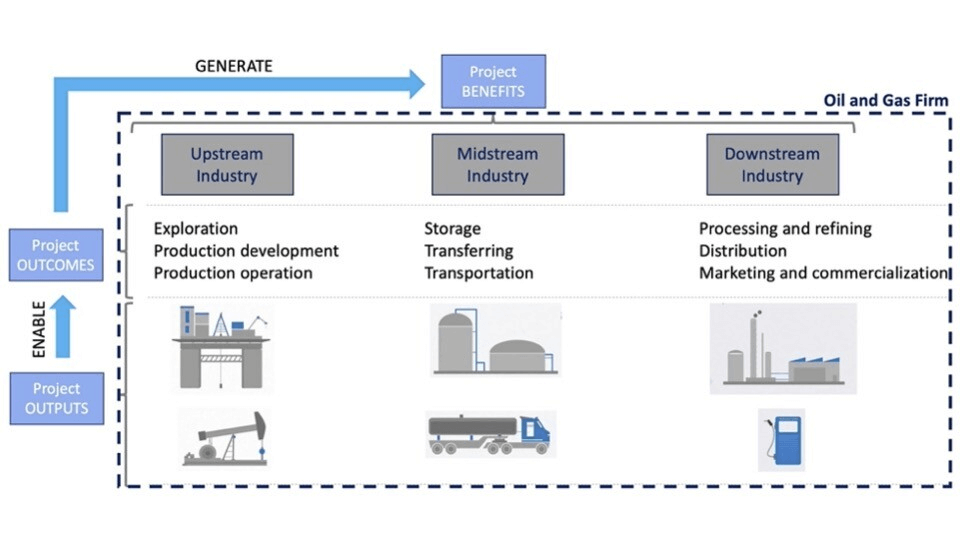

- Oil and Gas Industry:

In the oil and gas sector, honed tubes are indispensable for hydraulic systems in drilling equipment and offshore platforms, offering vital high-pressure resistance for reliable operation in challenging professional environments. Learn more about the application of honed tubes within the oil and gas industry.

Find high-pressure honed tubes suitable for drilling systems.

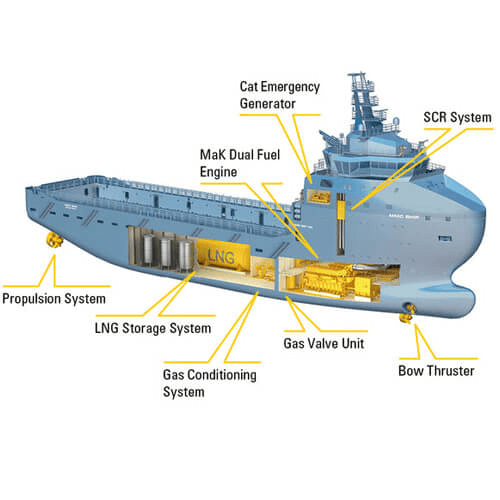

- Marine Applications:

The corrosion resistance of honed tubes makes them highly suitable for marine hydraulic systems, particularly in steering mechanisms, as they provide the durability necessary for equipment subjected to harsh marine conditions. Explore the use of honed tubes for marine applications.

Learn more about corrosion-resistant hydraulic tubing.

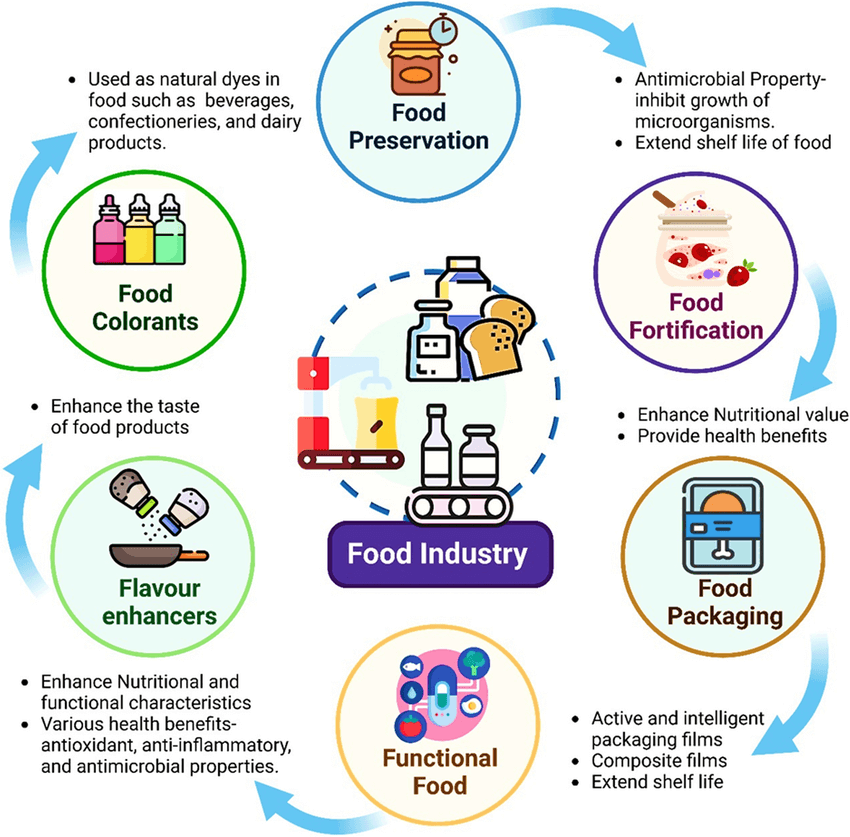

- Food and Pharmaceutical Industries:

Stainless steel honed tubes are utilized in hygienically critical environments such as food processing and pharmaceutical settings, where their smooth, polished interiors comply with strict cleanliness requirements, preventing contamination. Discover food-grade honed tubes.

Find hygienic tubing for sensitive environments.

Benefits of Using Industrial Honed Tubes

- Precision Engineering:

The honing process generates a mirror-like internal finish, critical for applications requiring minimal tolerances and smooth fluid dynamics. This precision is essential for systems operating in hydraulic and pneumatic cylinders. Explore the honing process for tubes.

View detailed specifications of honed tubing. - Enhanced Durability:

Honed tubes are manufactured from high-quality materials such as Cold Drawn Seamless (CDS) or Drawn Over Mandrel (DOM) steel. These materials are capable of withstanding challenging operating conditions, resulting in prolonged machinery lifespan. Discover resilient materials for honed tubing.

Learn about DOM and CDS honed tube options. - Improved Efficiency:

The smooth interior surface of honed tubes reduces friction, enhancing fluid flow, decreasing wear, and trimming energy consumption within hydraulic and pneumatic systems, thereby enhancing machinery efficiency. Explore the efficiency benefits of honed tubes.

Understand how honed tubes diminish wear in systems. - Customizable Sizes:

Honed tubes are available in various dimensions and can be tailored to meet specific application requirements, providing diverse design flexibility. This adjustability is particularly crucial for hydraulic cylinder manufacturers and equipment designers. Explore customizable sizing options for honed tubes.

Download a honed tube size chart for reference. - Reduced Maintenance Needs:

The durability and precision of honed tubes contribute to diminished maintenance requirements, lowering operational downtime and enhancing productivity in industrial equipment. Discover low-maintenance honed tube solutions.

Learn about long-lasting honed tubing suitable for heavy-duty use.

Conclusion

Industrial honed tubes are indispensable in a wide range of sectors, enhancing the functionality, efficiency, and reliability of hydraulic and pneumatic systems. Their precise engineering and robust material properties make them essential for modern machinery across industries.