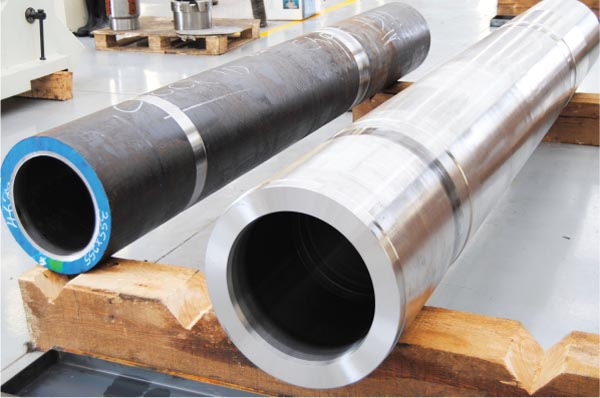

Honed pipes represent precision-engineered tubes frequently utilized in hydraulic and mechanical systems, renowned for their precise specifications and internally sleek surfaces achieved through the honing process.

The definition of honed pipes encompasses critical specifications such as inside and outside diameters, wall thickness, and mechanical properties, including yield strength and tensile strength. These details guarantee precision and reliability, rendering honed pipes highly suitable for hydraulic cylinders, pneumatic systems, and various automotive applications.

Comprehensive insights on honed pipe standards and applications

In-depth exploration of honed pipe specifications for hydraulic systems

This examination will provide a detailed overview of honed pipe specifications, encompassing materials, production, dimensions, and application scenarios.

What is a Honed Pipe?

A honed pipe is a cylindrical tube subjected to a honing process to create a smooth internal surface, minimizing friction. This feature is particularly desirable in applications such as hydraulic cylinders where a sleek bore helps reduce the wear of components.

Sub Snippet Paragraph: Honed pipes feature polished, smooth interiors that make them well-suited for hydraulic and pneumatic systems, where low friction and precise dimensional accuracy are vital.

Further information on honed pipe applications

Explore the benefits of honed pipes in precision engineering

Material Grades of Honed Pipes

Honed pipes are often manufactured using robust materials including E355 (EN 10305-1) , ST52-3 (DIN 2391) , as well as other grades like ASTM A519 and JIS STPT410. These materials are selected for their strength and compatibility with specific applications.

SubSnippetParagraph: E355 and ST52-3 are common materials used in honed pipes due to their high strength and applicability in hydraulic and pneumatic systems.

Comprehensive information about the materials and grades of honed pipes

An in-depth overview of steel grades for honed tubes

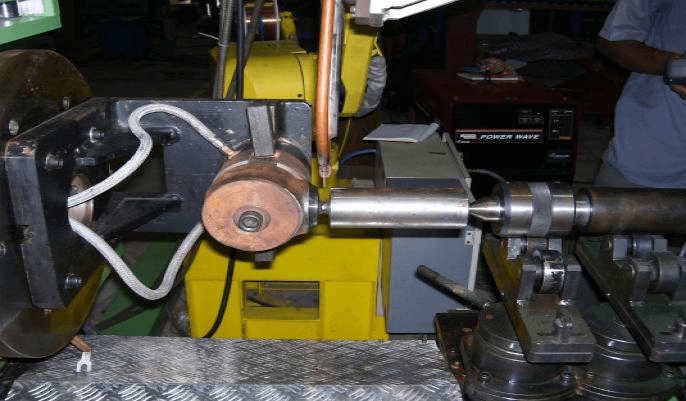

What are the Manufacturing Processes for Honed Pipes?

Honed pipes are manufactured using processes such as cold drawing and hot finishing, which are followed by honing or skiving and roller burnishing to achieve smooth internal surfaces. There are both seamless and welded options, each suitable for specific applications based on pressure and precision requirements.

Sub Snippet Paragraph: The manufacturing processes, including cold drawing and hot finishing, are designed to ensure honed pipes fulfill the exacting demands of high-pressure applications such as hydraulic cylinders.

In-depth understanding of the honed pipe manufacturing process

Manufacturing details for honed cylinders

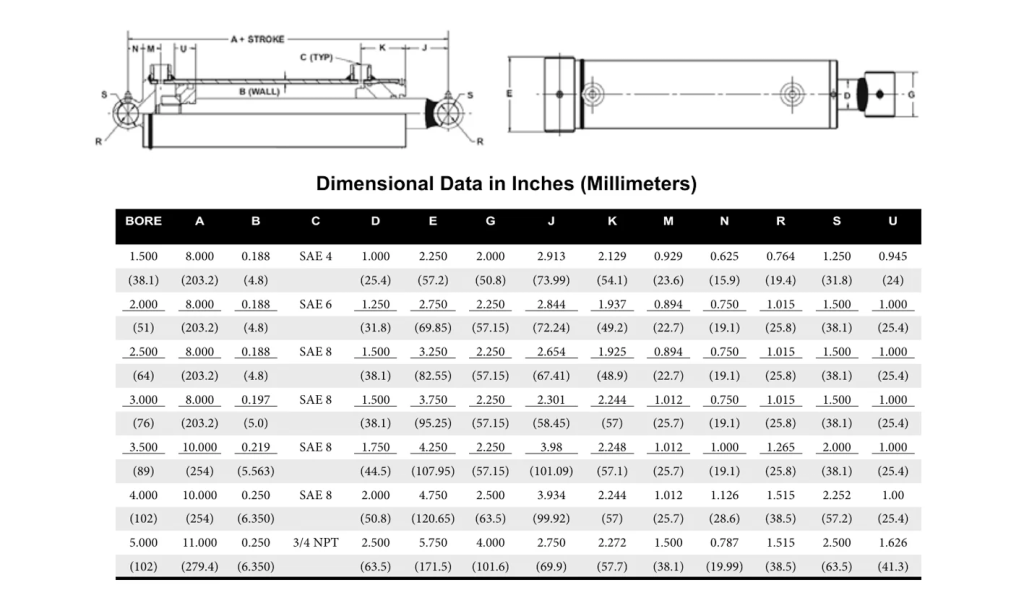

Dimensions and Tolerances of Honed Pipes

Honed pipes are available in various sizes with inside diameters (ID) ranging from 32mm to 800mm (metric) and 1" to 24" (imperial). The outside diameters (OD) typically vary according to the ID. Wall thicknesses vary from 4mm to over 20mm, depending on the specific application requirements.

Sub Snippet Paragraph: Honed pipes come in a range of dimensions with tolerances such as H7 and H9 to ensure they fulfill rigid application requirements in hydraulic and mechanical systems.

Review honed tube size charts

Detailed honed pipe specifications

Mechanical Properties of Honed Pipes

Honed pipes are notable for their impressive mechanical properties. For instance, pipes with an E355 grade exhibit a yield strength of at least 520 MPa and a tensile strength of up to 600 MPa. This high level of strength enables the pipes to withstand hydraulic pressures, with an elongation of approximately 15% contributing to their durability.

Sub Snippet Paragraph: The robustness of honed pipes is essential for high-performance applications, with grades such as E355 ensuring reliability and resilience under high pressures.

Overview of mechanical properties of honed pipes

In-depth information about the strength of honed pipes

Mechanical Properties of Honed Pipes

Honed pipes are notable for their impressive mechanical properties. For instance, pipes with an E355 grade exhibit a yield strength of at least 520 MPa and a tensile strength of up to 600 MPa. This high level of strength enables the pipes to withstand hydraulic pressures, with an elongation of approximately 15% contributing to their durability.

Sub Snippet Paragraph: The robustness of honed pipes is essential for high-performance applications, with grades such as E355 ensuring reliability and resilience under high pressures.

Overview of mechanical properties of honed pipes

In-depth information about the strength of honed pipes

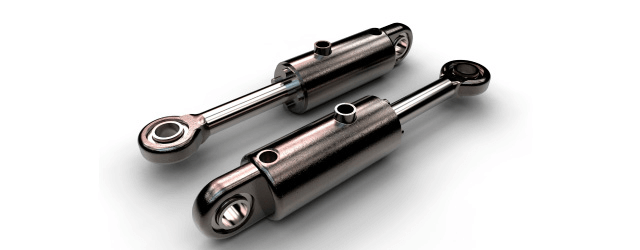

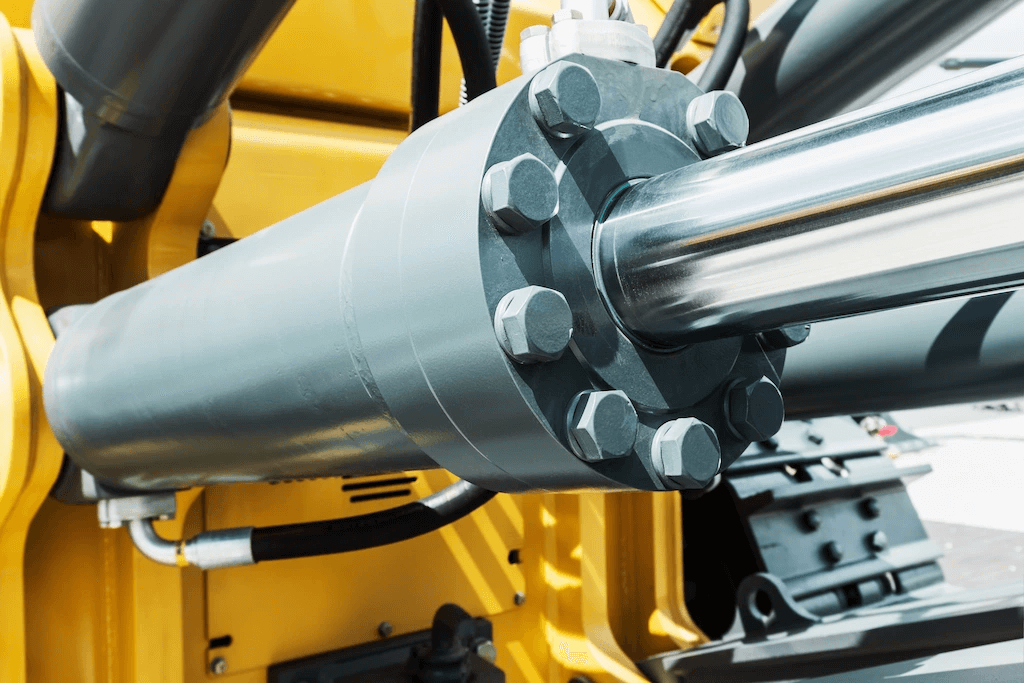

Applications of Honed Pipes

Honed pipes play a crucial role in hydraulic cylinders, pneumatic systems, automotive components, and various mechanical engineering applications. These pipes are well-regarded for their precision, smoothness, and robustness, which makes them particularly well-suited for systems demanding low friction and high dependability.

Sub Snippet Paragraph: Honed pipes are widely employed across industries requiring precise actuation and durability, including hydraulic and automotive applications.

Detailed explanations of honed pipe applications

Industrial applications of honed cylinder tubes

Length Options for Honed Pipes

Honed pipes are offered in standard lengths of up to 12 meters, with custom lengths being available upon request. The length of the pipe holds significant importance in compatibility with various applications, particularly within industries that require extensive fluid transportation.

Sub Snippet Paragraph: Standard honed pipe lengths extend to 12 meters, with the option for custom lengths to accommodate specific industrial requirements.

Discover honed pipe length options

Guidance on selecting the appropriate honed pipe length

Summary of Specifications

| Specification | Metric Sizes | Imperial Sizes |

|---|---|---|

| Inside Diameter (ID) | 32 mm to 800 mm | 1" to 24" |

| Outside Diameter (OD) | Varies by ID | Varies by ID |

| Wall Thickness | 4 mm to over 20 mm | Based on ID |

| Yield Strength | Min 520 MPa | Varies by grade |

| Tensile Strength | Up to 600 MPa | Varies by grade |

| Length | Up to 12 m | Custom lengths |