Honed aluminum tubes are highly precise components prized for their lightweight composition, durability, and impeccably smooth surface finish. They are indispensable in industries focusing on weight reduction and resistance to corrosion, such as aerospace and automotive manufacturing.

Honed aluminum tubes offer a superb combination of lightweight construction, durability, and anti-corrosive properties. The refined surface on the interior significantly reduces friction, contributing to their suitability in hydraulic and pneumatic systems across diverse applications.

This content provides a comprehensive overview of the attributes, applications, and advantages of honed aluminum tubes, aiding manufacturers and engineers in their decision-making process, guiding them toward optimal choices for high-performing, lightweight, and corrosion-resistant solutions.

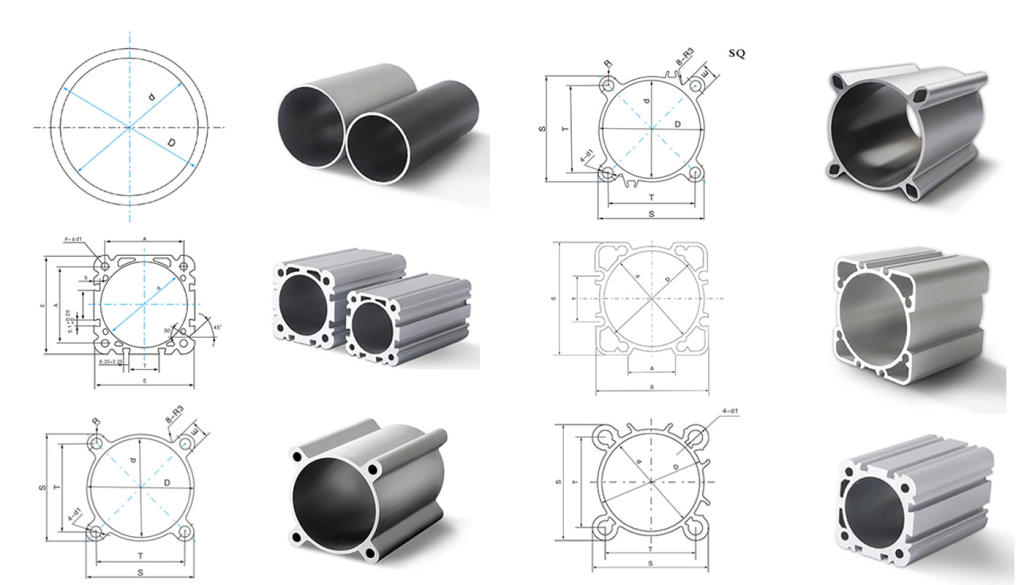

Key Attributes of Honed Aluminum Tubes

Material Composition:

Honed aluminum tubes are commonly fashioned from lightweight yet robust aluminum alloys, including 6061 and 6063. These materials are selected for their combination of strength, resistance to corrosion, and machinability. As a result, they provide an ideal strength-to-weight ratio suitable for diverse industrial and structural applications.

Explore 6061 and 6063 aluminum alloys

Overview of aluminum alloy properties

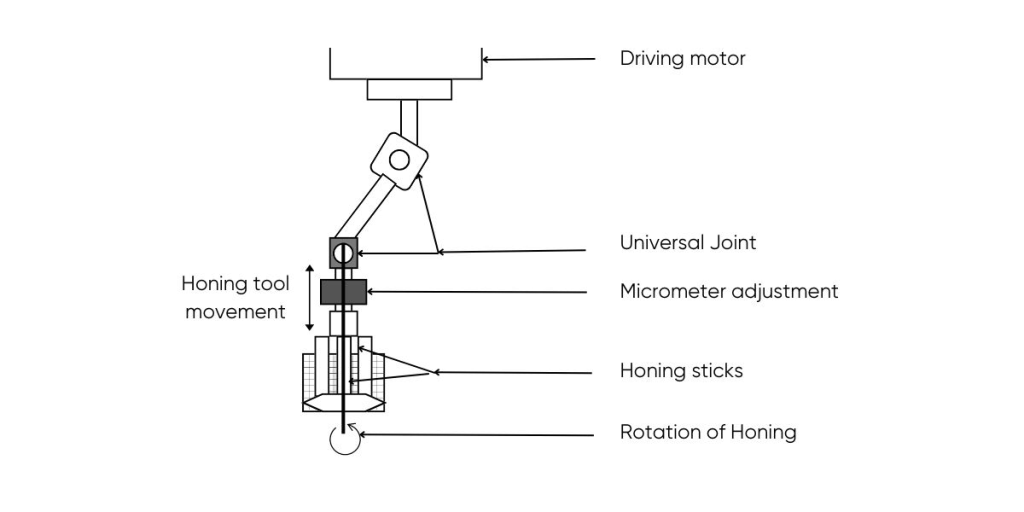

Honing Process:

The honing process involves the utilization of abrasive tools to achieve a meticulously honed, precisely dimensioned internal diameter within the tube, ensuring stringent tolerances. The resulting smooth surface minimizes friction and wear while enhancing the efficiency of moving components within hydraulic and pneumatic systems.

Understanding the honing process

How honing benefits hydraulic cylinders

Surface Finish:

As a consequence of the honing procedure, honed aluminum tubes boast a polished inner surface, featuring low roughness values typically rated at Ra 0.25 µm or better. This level of refinement is crucial for reducing wear on dynamic components and mitigating energy losses attributable to friction.

More on surface finish standards

Why surface finish matters in hydraulics

Dimensions:

Honed aluminum tubes are available in varied dimensions to accommodate specific requirements across a range of applications. Customization for honed aluminum tube sizes is a frequently offered service, guaranteeing precisely tailored configurations that align with machinery and systems requisites.

Custom sizes for honed tubes

Dimensional options for honed tubes

Applications of Honed Aluminum Tubes

Aerospace Sector

Honed aluminum tubes play a pivotal role in aerospace applications, particularly in landing gear and hydraulic systems that demand lightweight, robust materials. Their corrosion resistance and lightweight properties make them valuable in aircraft pneumatic systems, crucial to improving fuel efficiency and overall flight performance.

Automotive Industry

In the automotive industry, honed aluminum tubes are utilized in components such as shock absorbers and suspension systems to diminish the overall weight of vehicles, contributing to an enhanced fuel economy. These tubes also find application in the construction of lightweight frames and structural components, bolstering the production of fuel-efficient, high-performance automobiles.

Industrial Machinery

Honed aluminum tubes offer excellent performance within hydraulic cylinders and pneumatic actuators, ensuring smooth operation and the reduction of friction, particularly crucial in precision motion control. The combination of durability and refined surface quality renders them well-suited for machine tooling applications requiring dependable, high-quality components.

Food Processing and Packaging

Honed aluminum tubes are embraced for food processing machinery and packaging equipment due to their corrosion resistance, fostering easy cleaning and maintenance within critical hygiene-sensitive environments. These tubes support efficient machinery operation in environments subject to moisture and various other elements.

Oil Drilling

In the oil and gas sector, honed aluminum tubes are commonly featured in equipment requiring durable, lightweight tubing for fluid conveyance under pressure. Their amalgamation of strength, anti-corrosive properties, and low weight render them valuable in drilling and extraction operations.

It is important to note that these applications highlight the diverse versatility and adaptability of honed aluminum tubing across multiple industries, underscoring its essential role in fueling technological progress and addressing specific industry demands.

Benefits of Honed Aluminum Tubes

Lightweight

Honed aluminum tubes offer reduced weight compared to steel alternatives, a crucial characteristic in applications such as aerospace and automotive industries, where mass reduction directly impacts efficiency and performance.

Why aluminum is lightweight

Benefits of lightweight materials in industries

Corrosion Resistance

Aluminum naturally displays resistance to corrosion, rendering honed aluminum tubes ideal for environments exposed to moisture, chemicals, or corrosive elements, such as those encountered in food processing or marine applications. This corrosion resistance extends longevity and reduces maintenance requirements.

Corrosion-resistant properties of aluminum

Corrosion resistance in industrial tubing

Enhanced Performance

The honing process yields a smooth internal surface with minimal friction, resulting in improved efficiency within hydraulic systems. By minimizing abrasive wear on moving parts, the smooth bore interior enhances machinery longevity and improves overall system performance.

Performance advantages of honed surfaces

Honing benefits in hydraulics

High Strength-to-Weight Ratio

Aluminum alloys, including 6061 and 6063, provide exceptional strength while maintaining lower weight characteristics compared to steel. This superior strength-to-weight ratio positions honed aluminum tubes as a favorable material choice for structural and precision applications requiring robustness and lightness.

Strength-to-weight comparison: Aluminum vs. Steel

Why strength-to-weight matters

Versatility

Honed aluminum tubes demonstrate versatility across various industries, including automotive, aerospace, food processing, and industrial machinery, reflecting the material’s adaptability to diverse environments and applications. This broad adaptability, epitomized by the harmonious fusion of unique properties, characterizes the versatile nature of honed aluminum tubing.

Versatility of honed aluminum tubes

Applications across industries

Conclusion

Honed aluminum tubes offer lightweight construction, corrosion resistance, and precision finishing, making them essential in industries like aerospace, automotive, and industrial machinery. Their unique characteristics enhance performance, efficiency, and durability, supporting applications that demand high-quality, low-maintenance materials.

Here's a table covering the material types, models, applications, and specifications of honed aluminum tubes.

| Material | Model | Application | Specifications |

|---|---|---|---|

| 6061 Aluminum | 6061-T6 | Aerospace (hydraulic systems, landing gear) | High strength-to-weight ratio, corrosion resistance, customizable sizes |

| 6063 Aluminum | 6063-T5 | Automotive (shock absorbers, suspension) | Excellent surface finish, machinability, smooth bore for reduced friction |

| 7075 Aluminum | 7075-T6 | High-stress environments (aerospace, defense) | Exceptional strength, lightweight, ideal for load-bearing applications |

| 5052 Aluminum | 5052-H32 | Food processing and packaging | High corrosion resistance, easy to clean, compliant with food-grade standards |

| 5083 Aluminum | 5083-O | Marine and oil drilling | Superior corrosion resistance in saltwater, durable under pressure |