Struggling to choose the right part for your pneumatic system? If you need a smooth, straight tube, select a tube that has been honed over one that is just drawn over. Getting the best quality honed tube for your pneumatic cylinders is important. Don’t skimp on this critical component that can impact the precision, durability, and efficiency of your cylinder.

Key Features of Pneumatic Cylinder Honed Tubes

1. Precision Internal Finish

Utilizing honed tubes with smooth internal surfaces featuring a roughness level of Ra 0.2 to 0.4 micrometers significantly reduces friction and wear. This precision internal finish plays a vital role in facilitating the smooth movement of the piston within pneumatic cylinders.

For further insights on surface finishes, see here, and to learn more about honing standards, access this resource.

2. Dimensional Accuracy

The honing process ensures the internal diameter meets precise tolerances, such as H8 or H9. This level of accuracy guarantees the proper function of seals and components, improving system reliability.

Read about tolerance standards and dimensional accuracy in honed tubes.

3. Material Options

Honed tubes are available in materials like ST52 steel, stainless steel, and aluminum, offering versatility based on application needs. Steel provides strength, aluminum ensures lightweight options, and stainless steel resists corrosion.

Explore material options here and material selection tips here.

4. Enhanced Performance

Honed tubes improve lubrication, reduce wear, and enhance sealing performance. This ensures pressure retention and efficiency, key factors for reliable pneumatic cylinder operations.

Discover performance benefits and sealing technology.

5. Versatile Applications

These tubes find applications in manufacturing, robotics, and automotive industries. Their precision and reliability make them indispensable in automation, control, and other pneumatic processes.

Learn about industrial applications and automation solutions.

Manufacturing Process of Honed Tubes

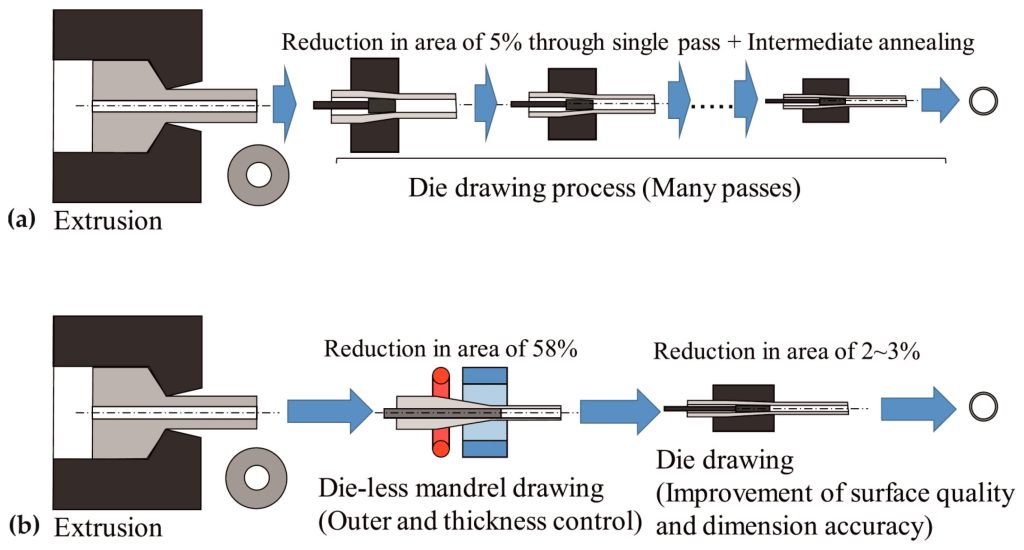

Tube Formation

Base tubes are formed through extrusion or cold drawing to ensure structural integrity and dimensional consistency.

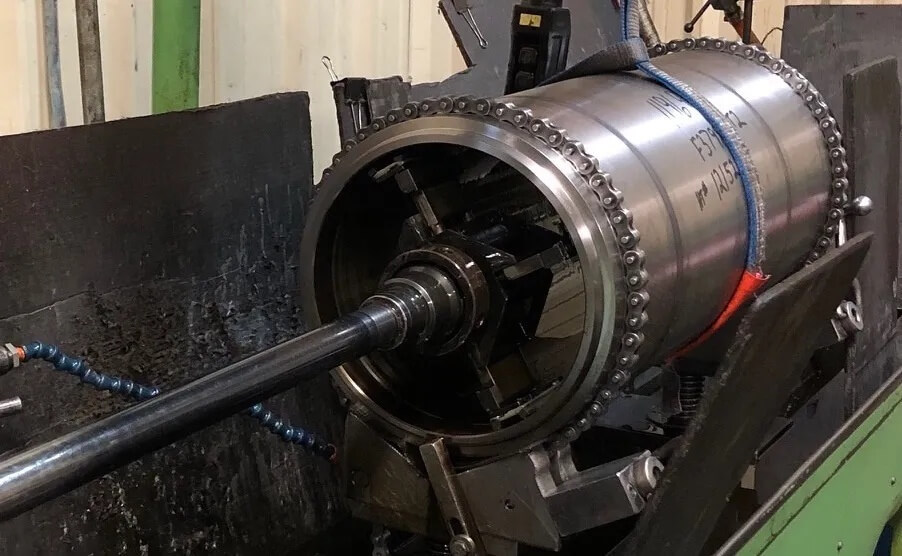

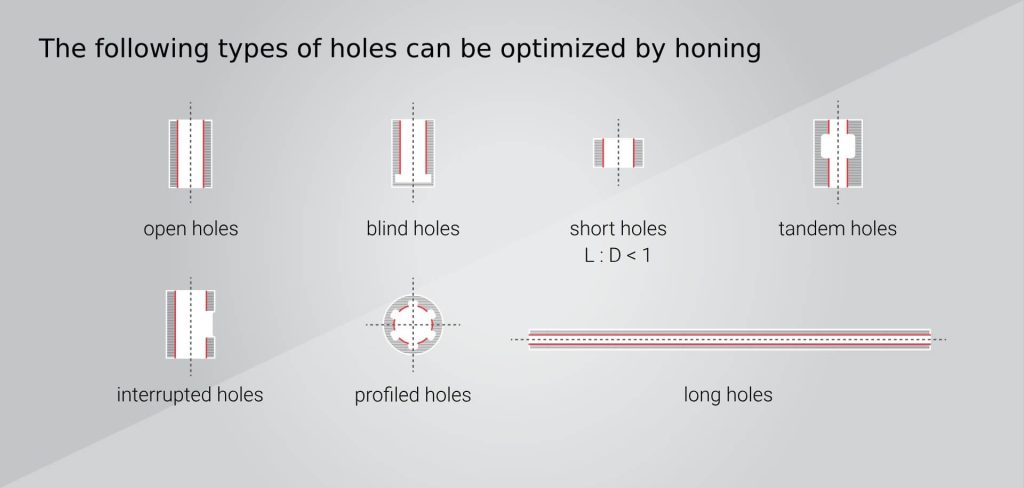

Honing

The internal surface undergoes honing using abrasive stones to achieve the desired finish and dimensional precision.

Quality Control

Each tube is rigorously inspected to meet specific tolerances and surface standards, ensuring reliability in critical applications.

Read about manufacturing techniques and quality control methods.

Conclusion

Pneumatic cylinder honed tubes play a pivotal role in delivering precision, durability, and peak performance within pneumatic systems. The honing process is instrumental in establishing the required smooth internal surfaces and tight dimensional tolerances, essential for fostering efficient and reliable performance across various industries.

For additional information or to explore honed tube options, visit honingpipe.com or reach out to the team at [sales@cnsteelsupplier.com].