What are Cold Drawn Honed Tubes?

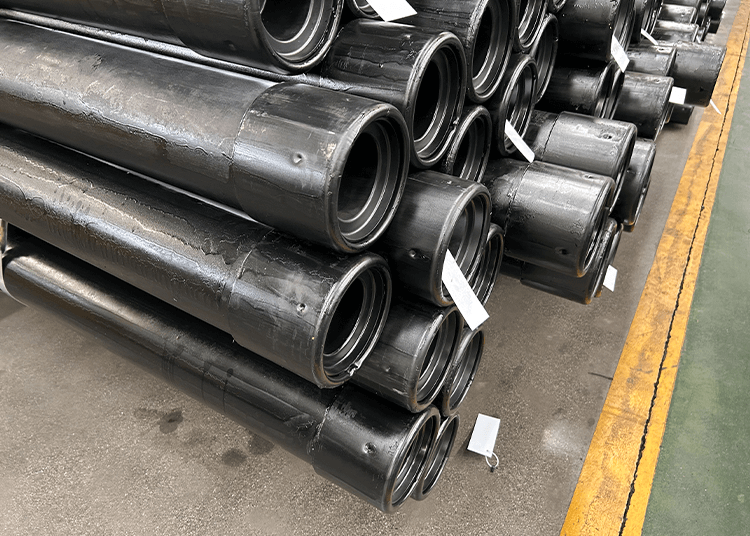

Cold Drawn Honed Tubes are the high precision tubes that find applications in various hydraulic systems, especially in the hydraulic cylinders. The sturdy construction and the essential features of steel material make the hydraulic systems to withstand the very high pressures and the corrosive effects of the hydraulic and the pneumatic systems.

Check our the site Cold Drawn Tubes | Hydraulic system tubing.

The combination of cold drawing and honing results in the production of tubes with exceptionally precise dimensional accuracy and a smooth surface, making them ideal for hydraulic applications wherein friction needs to be minimized.

Precision tubing explained | Hydraulic cylinder tubes.

Cold drawn honed tubes serve as a preferred choice due to their precision, smooth surface finish, and resistance to corrosion. These properties make them invaluable for applications where fluid efficiency and durability are essential. Let’s dive into this further and unravel the specifics of their manufacture and applications.

Manufacturing Process

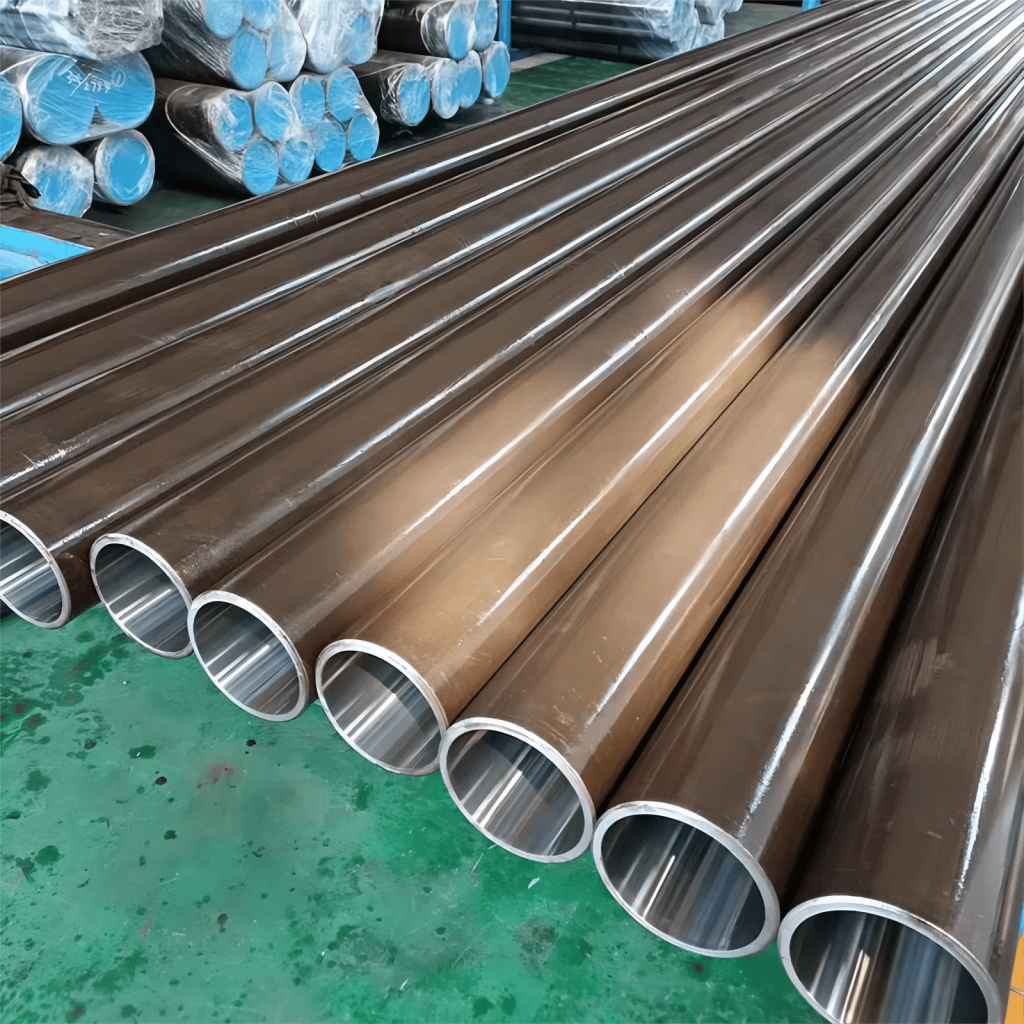

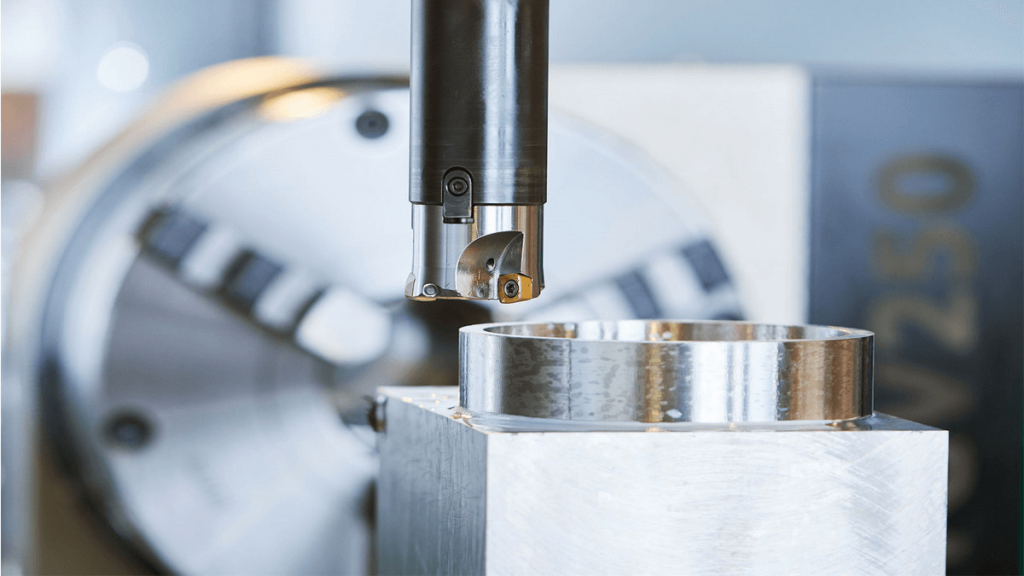

Cold Drawing

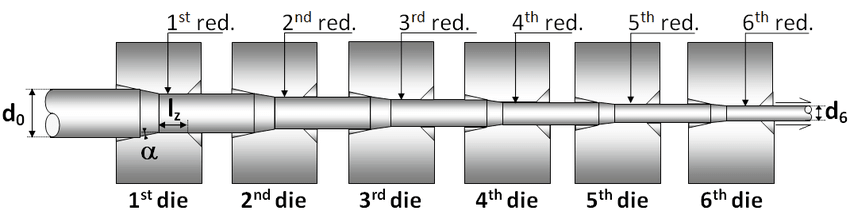

Cold drawing refers to the process of pulling steel through dies at low temperatures to refine the dimensions of the tube. This technique increases strength and durability, making these tubes suitable for various industrial applications. Learn more about cold drawing | Insight into cold drawn tubes.

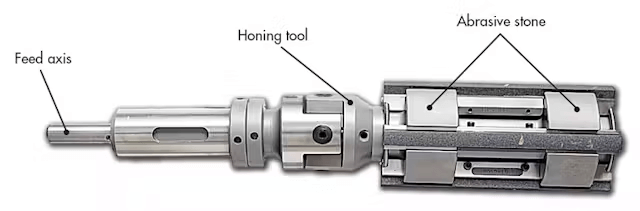

Honing

Following the cold drawing process, honing is utilized to polish the interior of the tube. Abrasive stones smooth the surface, eliminating imperfections and creating a sleek finish that minimizes friction within hydraulic systems. This smooth finish is critical for efficient fluid flow. Explore the honing process | Insight into the honing process.

Key Features of Cold Drawn Honed Tubes

High Precision

Cold drawn honed tubes are produced to precise tolerances, meeting the rigorous demands of hydraulic systems and ensuring consistent fittings. This precision helps prevent leakage, reducing downtime and maintenance costs. Specifications for cold drawn honed tubes | Precision tubing features.

Smooth Surface Finish

The honing process creates an exceptionally smooth interior that minimizes turbulence and improves fluid flow, enhancing the efficiency of hydraulic applications by reducing energy loss. Surface finish benefits | Efficient fluid transmission.

Corrosion Resistance

Depending on the material, such as stainless steel, cold drawn honed tubes exhibit effective corrosion resistance, making them suitable for extended use in diverse environments. Corrosion-resistant tubing | Materials for honed tubes.

Applications of Cold Drawn Honed Tubes

- Hydraulic Cylinders

Cold drawn honed tubes serve as the cylinder barrels in hydraulic systems, ensuring smooth piston movement. They assist in converting hydraulic energy into indicative motion for precision mechanical function. Utilization in hydraulic applications | Cylinder tubing applications. - Automotive Industry

These tubes are used in various automotive applications, such as suspension and braking systems, where precise control of fluids is critical for safety and performance. Application in the automotive industry | Tubing in automotive use. - Construction Machinery

Essential components in heavy machinery like excavators and loaders to withstand tough working conditions. Application in construction industry | Durable tubing for machinery. - Mining Equipment

The robust nature and resistance to harsh conditions render cold drawn honed tubes highly suitable for use in mining machinery. Application in mining industry | Tubing for challenging conditions.

Advantages of Cold Drawn Honed Tubes

Enhanced Efficiency: The smooth inner surface of these tubes enables fluid transmission at an accelerated and consistent pace, thereby reducing energy loss and optimizing hydraulic system performance. (Learn more about efficiency) | (Improving performance).

Superior Durability: Cold drawn honed tubes provide exceptional longevity owing to the implementation of high-quality materials and a meticulous manufacturing process, resulting in extended product lifespans and reduced maintenance expenses. (Discover the advantages of durable tubing) | (Long-lasting materials).

Customization Options: Available in diverse sizes and materials, cold drawn honed tubes can be tailored to meet the unique requirements of specific applications, thereby enhancing their overall adaptability and utility. (Explore custom tubing options) | (Flexibility in size and material).

Conclusion

Cold drawn honed tubes are indispensable in hydraulic systems for their precision, durability, and energy efficiency. As technology advances, these tubes are likely to see further enhancements, making them suitable for even more demanding applications across various sectors. Explore honed tubing | Industrial applications of honed tubes.