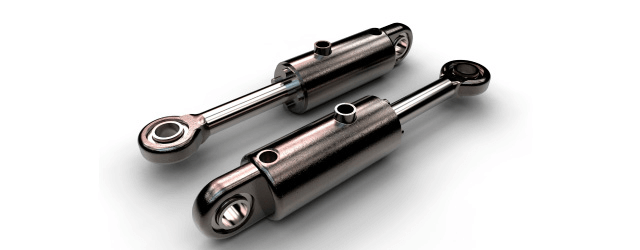

Hydraulic cylinders are critical components in many industrial applications, and while welding is possible, it requires careful preparation and precise execution to avoid structural damage or safety hazards. Here’s a comprehensive guide on how to weld hydraulic cylinders safely and effectively.

Is It Safe to Weld Hydraulic Cylinders?

It’s not a matter of if you can weld hydraulic cylinders, but you must prepare and execute with care to avoid damage. Key factors include choosing the appropriate welding technique, making sure the cylinder is at a zero-PSI state, and if possible, you disassemble the cylinder to save sensitive parts from heat. By taking these steps, you can significantly reduce risk – especially when welding the rod end of the hydraulic cylinder or tank fittings.

Key Considerations for Welding Hydraulic Cylinders

1. Presence of Oil in Cylinders

It is generally recommended to drain hydraulic fluid from the cylinder prior to welding to avoid fire hazards and contamination. However, some welders have successfully welded with oil inside the cylinder by utilizing techniques to dissipate heat, for example, wrapping the rod with wet rags to cool it and reduce the risk of fire. Welding with the cylinder drained whenever possible is the safest method and helps protect the integrity of the hydraulic cylinder (K+S Services | Gear Sprocket).

2. Weld Location

Where you weld on the cylinder is paramount. You typically are safer welding near the ends of the cylinder or the fittings than directly on the cylinder’s body, especially if the cylinder is pressurized. If you are welding on a fitting, stay away from the body of the cylinder to keep heat from transferring, which might warp the cylinder or damage the seals (Cylinders, Inc. | Hydraulic Cylinders Net).

3. Welding Techniques and Materials

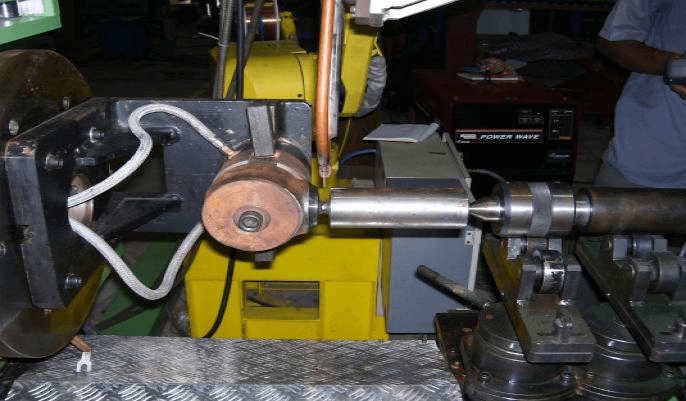

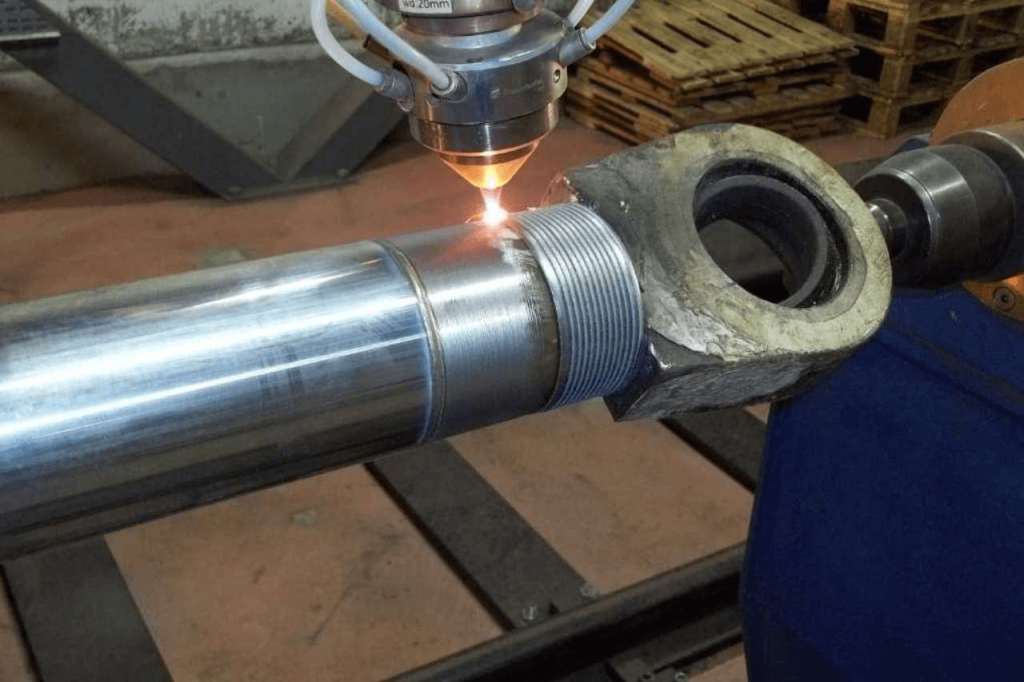

MIG and TIG welding are common techniques for welding hydraulic cylinders. TIG is better for thinner materials or precise welds, while MIG works better, especially for larger, thicker sections. Full-penetration welding is typically preferred because of the added strength it provides. Preheating might be needed to prevent cracking on thicker materials, depending on the metal composition of your cylinder (Solutionslate | Cylinders, Inc.).

4. Managing Potential Damage to Cylinder Components

It is important to take measures to avoid damaging the chrome present on the cylinder rod, as the heat generated during welding can easily compromise this protective coating. Fully extending the rod and keeping it cool with wet rags during the welding process can help to mitigate the risk of thermal damage, preserving the rod’s durability and performance (Northern Hydraulics | K+S Services).

5. Professional Assistance

Due to the complexity and potential risks associated with welding hydraulic cylinders, seeking the guidance of a professional is often a prudent approach. Expert hydraulic repair shops can provide valuable advice and assistance, ensuring compliance with safety standards while safeguarding the structural integrity of the cylinder (Cylinders, Inc. | K+S Services).

Can You MIG Weld a Hydraulic Cylinder?

Yes, MIG welding can effectively repair hydraulic cylinders, particularly for repairing thicker sections. To avoid damaging other components, careful heat control is crucial. TIG welding, however, is generally preferred for precise applications, especially with thinner or more delicate pieces. Using appropriate welding rods, such as low-hydrogen rods specifically for hydraulic cylinder repairs, can enhance the quality of the weld and reduce spatter (Hydraulic Cylinders Net | Solutionslate).

What Welding Rod to Use on a Hydraulic Cylinder?

For hydraulic cylinders made of mild steel, low-hydrogen rods like E7018 are commonly used because of their strong bonding characteristics and minimal spatter. Considering the tensile requirements of the material is important for selecting the right welding rod to create a secure weld that can withstand hydraulic pressure (K+S Services | Cylinders, Inc.).

Can You Fix a Leaking Hydraulic Cylinder?

Welding can sometimes resolve a leaking cylinder if the issue stems from a structural crack. However, other causes of leaks, such as seal failures, may require specific repairs or the replacement of parts. Following any weld repair, it is imperative to test the cylinder while pressurized to confirm the resolution of the leak and ensure the unit operates safely (Northern Hydraulics | Gear Sprocket).

Conclusion

Although welding hydraulic cylinders can be an effective repair method, it requires careful planning, technical expertise, and adherence to safety standards to mitigate potential hazards. For critical applications, seeking professional assistance is advisable to ensure safety and preserve performance.