Honed tubes face challenges in meeting strict quality standards for hydraulic applications. This requires robust quality control measures.

Honed tubes undergo rigorous quality checks to ensure precision, durability, and optimal performance for hydraulic and industrial systems.

Keep reading to learn how these measures ensure the highest standards in honed tube production.

What are the main differences between honing and skiving & roller burnishing processes?

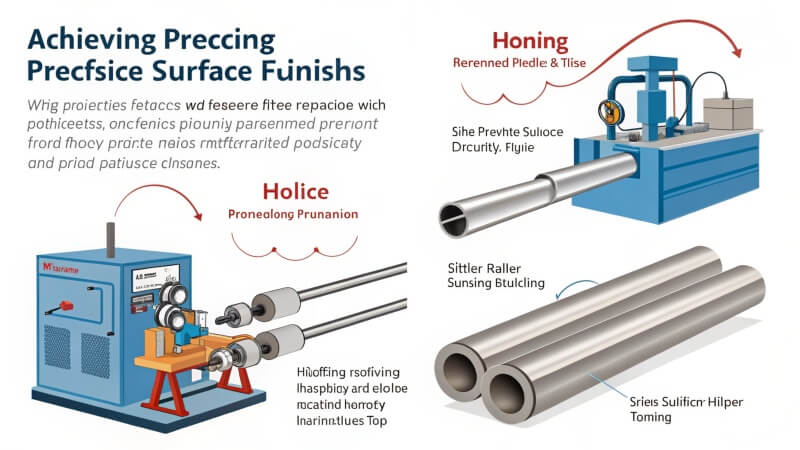

Honing and skiving & roller burnishing solve the challenge of achieving precise surface finishes in hydraulic tubes.

Honing removes material for better precision, while skiving & roller burnishing smoothens surfaces for improved durability and efficiency.

Dive Deeper: Comparing honing and skiving & roller burnishing

Honing involves abrasive machining, ensuring uniformity and precision. Skiving & roller burnishing combines cutting and surface compaction to achieve smooth finishes quickly.

| Process | Key Feature | Applications |

|---|---|---|

| Honing | Removes material for accuracy | Hydraulic cylinders |

| Skiving & Roller Burnishing | Fast, cost-effective surface finishing | Industrial machinery |

| Combination Techniques | Improved dimensional tolerance | Precision engineering |

Each method offers unique advantages. Manufacturers often choose based on production scale, cost, and end-use requirements.

How does the choice of steel material affect the performance of honed tubes?

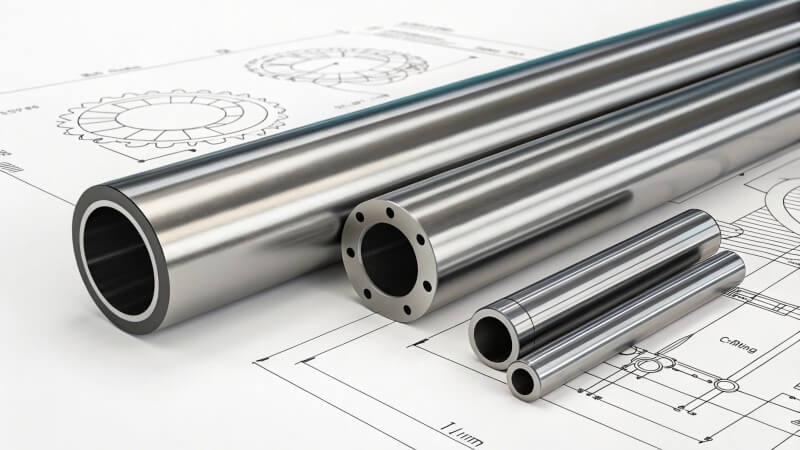

Choosing the right steel material solves the challenge of ensuring durability and performance under pressure.

Steel grade affects honed tube strength, wear resistance, and compatibility with hydraulic applications.

Dive Deeper: The importance of material selection

Different steel grades are used in honed tubes. Factors like tensile strength, machinability, and corrosion resistance determine their suitability for specific uses.

| Steel Grade | Key Properties | Common Uses |

|---|---|---|

| ST52 | High tensile strength | Hydraulic cylinders |

| E355 | Excellent machinability | Industrial machinery |

| Stainless Steel | Corrosion resistance | Harsh environments |

The choice of material impacts not only the performance but also the lifespan and reliability of the honed tubes in various applications.

What are the typical applications of honed tubes in hydraulic systems?

Honed tubes solve issues of efficiency and reliability in hydraulic systems through their precise dimensions and surface quality.

Honed tubes are essential for hydraulic cylinders, enabling smooth operation and reducing wear.

Dive Deeper: Applications in hydraulic systems

Honed tubes are critical in hydraulic systems where precise motion control is needed. They ensure smooth piston movement and prevent fluid leaks.

| Application | Function | Benefit |

|---|---|---|

| Hydraulic Cylinders | Guides piston movement | Reduces friction |

| Construction Equipment | Supports heavy loads | Increases durability |

| Industrial Machinery | Maintains system efficiency | Extends lifespan |

Honed tubes ensure hydraulic systems perform reliably even under demanding conditions.

How does the honing process improve the surface finish of tubes?

Honing solves the challenge of achieving smooth, precise surfaces in hydraulic tubes.

Honing improves the surface finish by removing imperfections and ensuring uniformity for optimal performance.

Dive Deeper: The honing process and its benefits

The honing process uses abrasive stones to remove minute amounts of material, resulting in precise dimensions and smooth finishes. This reduces friction and wear.

| Honing Process Stage | Purpose | Result |

|---|---|---|

| Rough Honing | Removes excess material | Prepares for fine honing |

| Fine Honing | Refines surface finish | Achieves precise tolerances |

| Final Inspection | Verifies quality | Ensures reliable performance |

The honing process enhances the functionality and lifespan of tubes used in hydraulic systems and other applications.

Conclusion

- Honing and skiving & roller burnishing offer distinct benefits for achieving precision and durability.

- Steel material choice impacts the strength, wear resistance, and compatibility of honed tubes.

- Honed tubes are essential in hydraulic systems for reliability and smooth operation.

- The honing process improves surface finishes, reducing friction and enhancing performance.

- Quality control measures ensure honed tubes meet strict industry standards.

Honed tubes combine precision and durability, making them indispensable for hydraulic and industrial applications.