Are you experiencing frequent failures in your hydraulic systems? The problem may be related to the quality of your cylinder barrels.

Honed ID steel tubes are precision-engineered components that are essential for hydraulic cylinder barrels, providing smooth internal surfaces and precise dimensions to ensure optimal performance and longevity. These tubes are manufactured from high-quality materials such as ST52 and SAE 4140, and undergo a detailed honing process to achieve superior surface finish and durability.

Understanding the significance of these tubes can lead to the development of more efficient and reliable hydraulic systems.

What Are Honed ID Steel Tubes?

Are you experiencing challenges achieving efficiency in your hydraulic systems? The culprit might be the tubing.

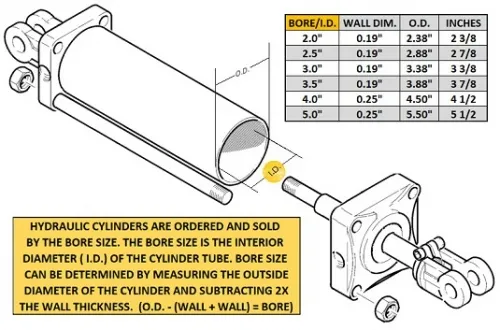

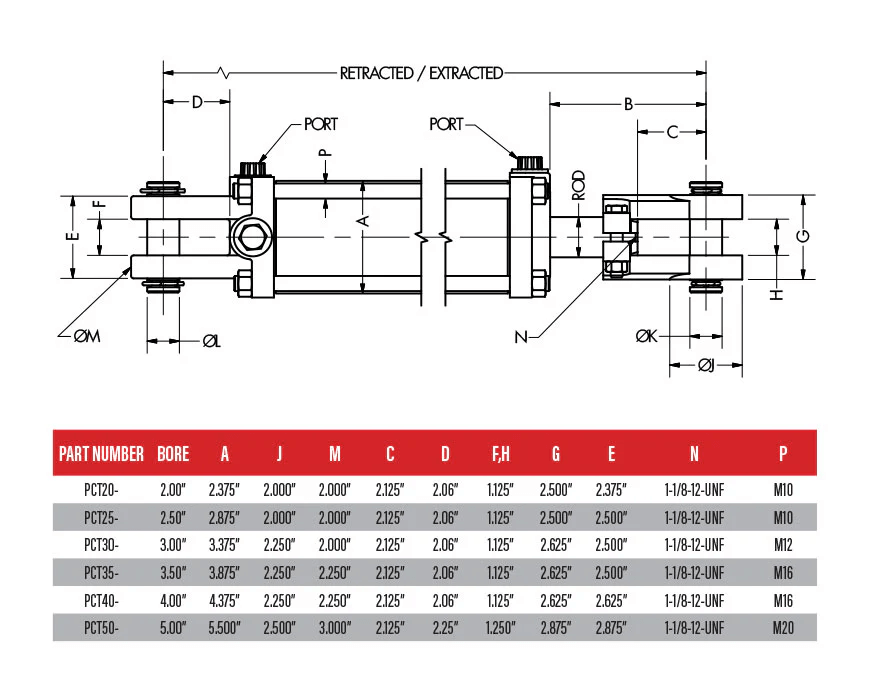

Honed ID steel tubes are cold-drawn seamless steel pipes that undergo a honing process, a precision machining technique that smoothens the inner diameter of the tube to a high degree. This treatment ensures the inner surface possesses superior finish quality, in turn reducing internal friction, diminishing wear and tear, and ultimately improving the operational efficiency of hydraulic cylinders. These tubes play a critical role in situations where exacting precision and high durability are warranted.

To gain an in-depth understanding of hydraulic cylinder tube dimensions, you can explore the resources available through Hydraulic Steels.

For more information about applications using honed ID steel tubes, visit Skyline Pipes.

What Are the Key Specifications of Honed ID Steel Tubes?

Are you curious about the materials and sizes that honed tubes come in? These two things greatly affect how a tube will perform in a particular application.

- Material Grades:

- SAE 1020: A low carbon steel that is easy to machine and weld.

- ST52: A high-strength steel that’s ideal for hydraulic systems because of its great mechanical properties.

- E355: This is similar to ST52 but for use in high pressure systems.

- SAE 4140: This is a chromium-molybdenum alloy steel that has high tensile strength and toughness.

- Size Range:

- Inner diameters can range anywhere from 32mm (1.25 inches) to 610 mm (24 inches)

- Outer diameters can vary greatly based on what the application needs are. They can range anywhere from 40mm x 30mm to 325mm x 300mm

For the full detailed chart of the sizes of the honed tubes, check out Skyline Pipes. You can also explore honed tube standard sizes in this fantastic and detailed PDF.

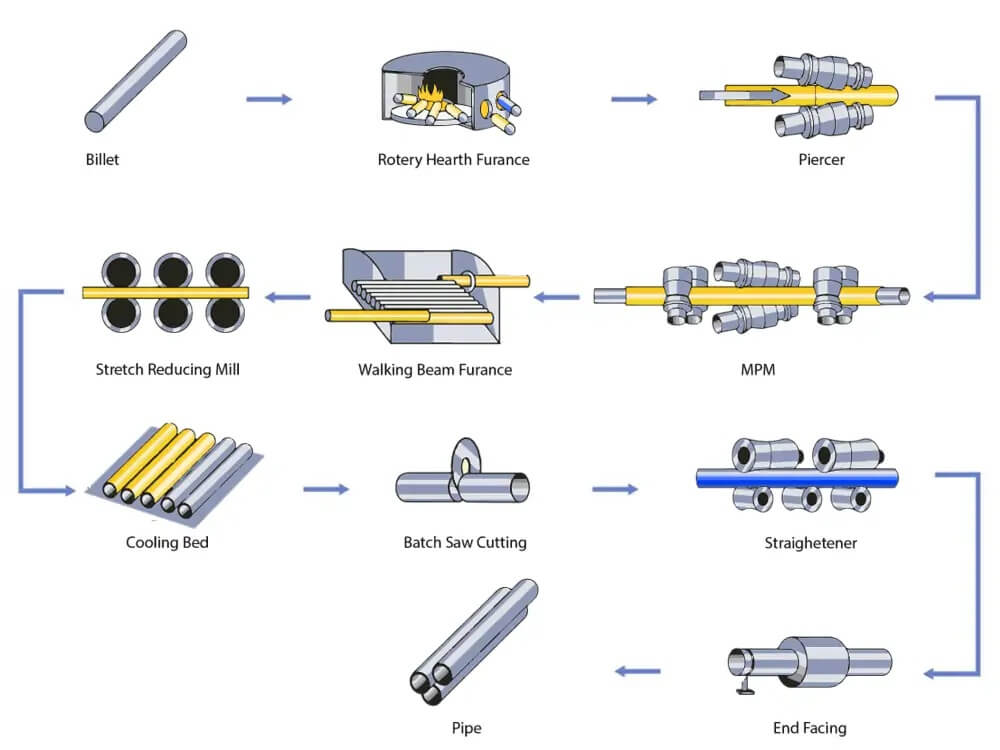

How Are Honed ID Steel Tubes Manufactured?

Are you wondering how honed ID steel tubes are made? The process is key to ensuring quality and performance.

- Cold Drawing:

- This process serves to improve mechanical properties, reduce defects, and enhance dimensional precision within the tubing.

- Honing:

- Concurrently, honing utilizes abrasive compounds to polish the inner surface of the tubing, creating a reflective finish critical for superior hydraulic performance.

By undergoing these crucial processes, honed ID steel tubes consistently meet the rigorous quality standards essential for their use in high-performance hydraulic systems. Learn more about the manufacturing process at Eastai Hydraulic. Explore local honed tube suppliers here.

What Are the Applications of Honed ID Steel Tubes?

Curious about where honed tubes are used? These applications cover a variety of industries.

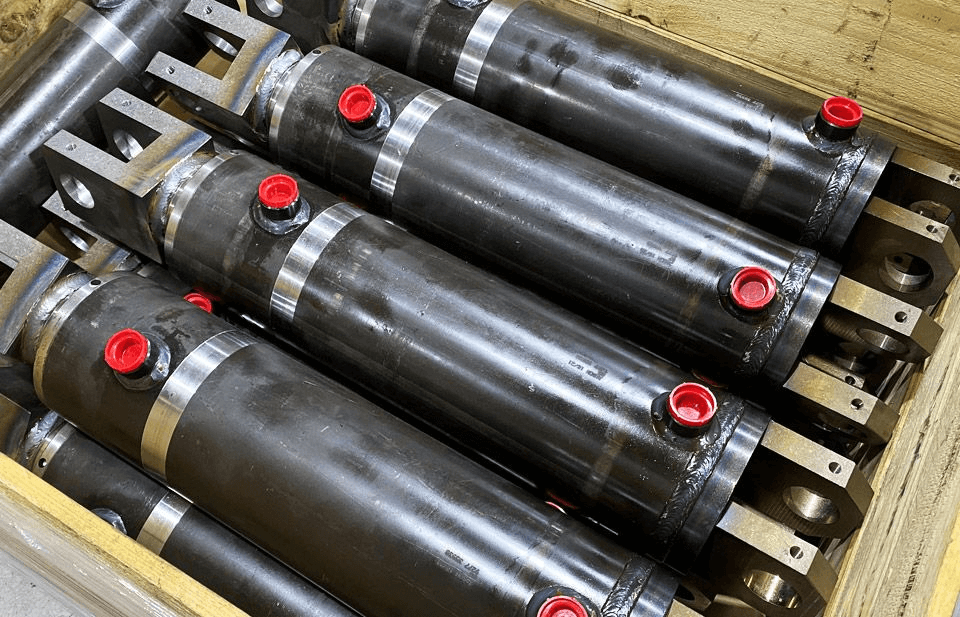

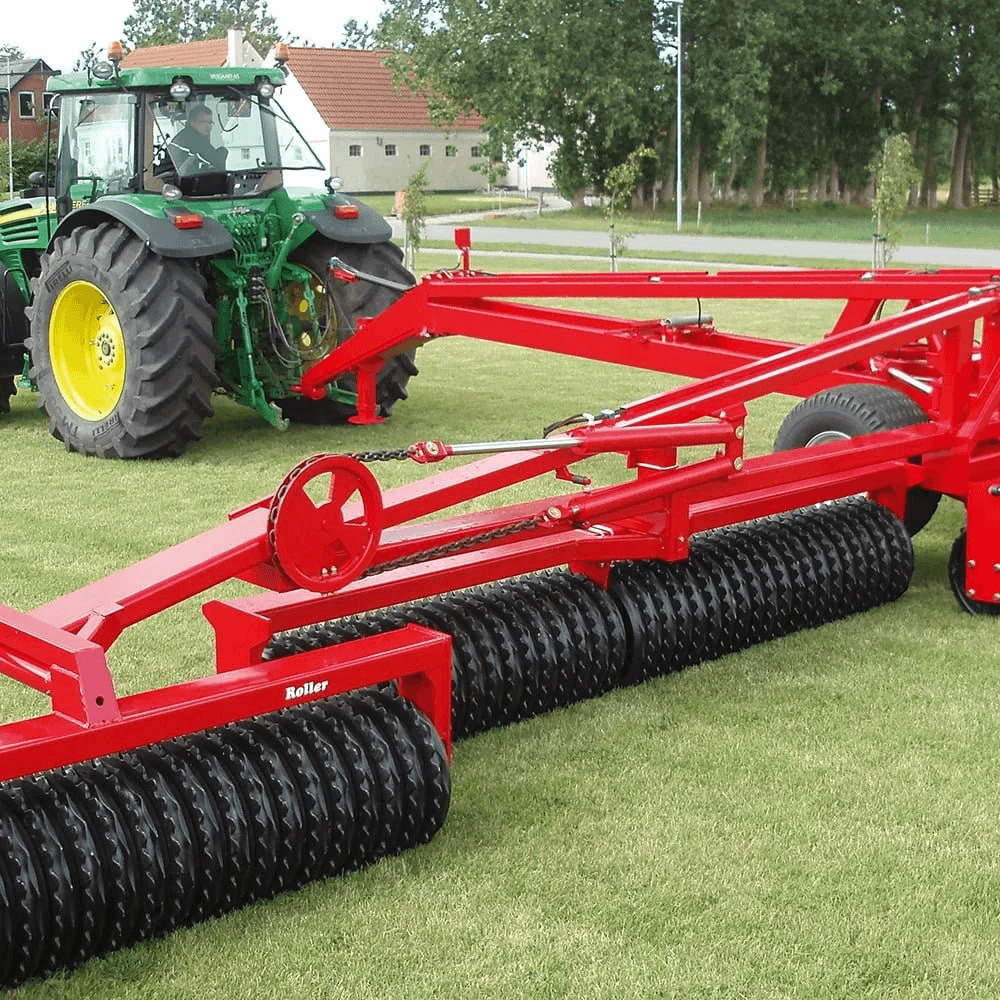

- Hydraulic Cylinders: The tubing forms the barrel for hydraulic fluid, allowing the piston to move smoothly and with little friction.

- Industrial Machinery: It’s used in equipment that runs on hydraulic or pneumatic power.

- Construction Equipment: It’s crucial for various pieces of machinery like excavators, front-end loaders, and other pieces of heavy equipment.

For more on how it’s used, head over to Hydraulic Steels. You can also explore the honed tube options necessary for hydraulic cylinders by going to Honed Pipe.

What Are the Advantages of Honed ID Steel Tubes?

Are you searching for tubing that provides precision and durability? Honed tubes offer a range of benefits that cannot be met with other types of tubing.

- Precision and Smoothness:

- The honing process creates a smoother, more precision bore with an excellent finish. As a result, the seals in the hydraulic system have less chance of leaking and the cylinder has less internal friction. This added smoothness translates into a more efficient hydraulic system.

- Durability:

- Honed and polished steel tubing is less prone to have chinks, cracks, and pits providing it is used in an appropriate environment with the required pressures. It must be handled with care during transport and assembly.

- Customization:

- Sizes and materials can be customized to meet different industry requirements.

Learn more about the benefits of honed tubing at Skyline Pipes. Find a honed tube supplier close to you here.

Conclusion

Honed ID steel tubes are absolutely essential for making reliable hydraulic systems that require precision, durability, and customization to operate high-performance machinery. They are made with care and attention to detail so that they can meet the strict standards of quality and performance that fluid power systems require, especially when it comes to hydraulic cylinders.

For all of the different products, sizes, and types of honed tubing, please visit Hydraulic Steels. If you are looking for competitive pricing, try Eastai Hydraulic.