Problem: Unable to find high-quality tubing for precision engineering applications?

Pain Point: Many manufacturers struggle to locate tubing that combines durability and precision.

Solution: Honed tubing provides the ideal solution for your needs, delivering exceptional accuracy and performance.

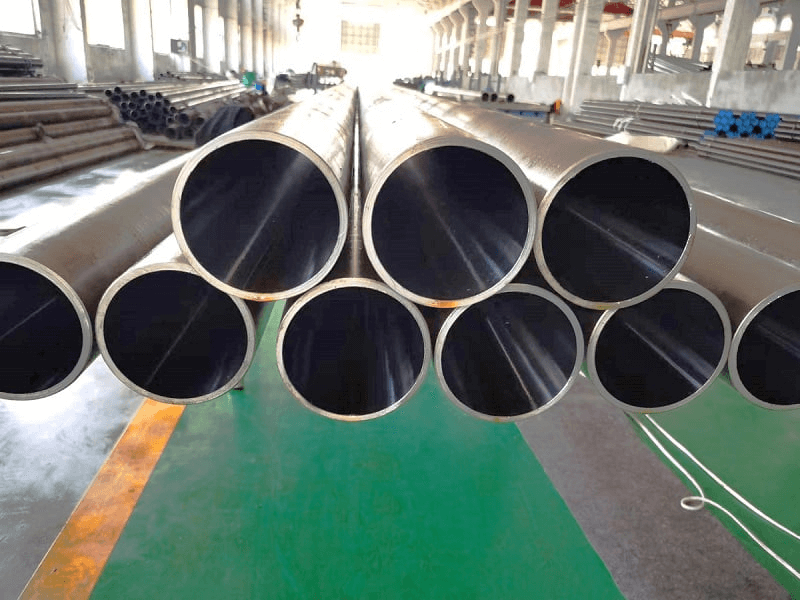

Honed tubing serves as an essential material for various high-precision applications, particularly in hydraulic systems, pneumatic cylinders, and machinery manufacturing. Through the honing process, honed tubes achieve a smooth internal surface and precise dimensions, critical for systems requiring both reliability and high performance.

Honed tubing is a specialized steel tube designed for precision engineering. The honing process ensures smooth surfaces and tight tolerances, making it ideal for applications like hydraulic cylinders, pneumatic systems, automotive components, and more.

If you are looking for “honed tubing near me”, suppliers offer a wide selection of sizes, and you can find the perfect options for your specific application. Whether you need it for a high-pressure hydraulic system or aerospace components, honed tubing is built to meet the most exacting standards.

Now that we’ve covered the fundamentals of honed tubing, let’s take a closer look at the manufacturing process, what materials are used, and the industries where it’s most commonly applied.

Typically, honed tubing is made from Cold Drawn Seamless (CDS) or Drawn Over Mandrel (DOM) steel. The honing process removes material from the inside surface to ensure tight tolerances and a polished finish. These tubes find extensive use in the industries where precision is a must, like in hydraulic cylinders and aerospace applications.

What is Honed Tubing and How is it Made?

Problem: Struggling to find high-quality tubing for precision engineering applications?

Agitation: Many manufacturers face challenges in sourcing tubing that offers both durability and precision.

Solution: Honed tubing provides the perfect solution for your needs, offering exceptional accuracy and performance.

Honed tubing is an essential material for various high-precision applications, particularly in hydraulic systems, pneumatic cylinders, and machinery manufacturing. By undergoing a honing process, honed tubes achieve a smooth internal surface and precise dimensions, which are crucial for systems that require both reliability and high performance.

Honed tubing is a specialized steel tube designed for precision engineering. The honing process ensures smooth surfaces and tight tolerances, making it ideal for applications like hydraulic cylinders, pneumatic systems, automotive components, and more.

If you're looking for honed tubing near me, suppliers offer a wide range of sizes, and you can find options that fit your specific needs. Whether it's for high-pressure hydraulic systems or aerospace components, honed tubing is designed to meet the most demanding standards.

Now that we've explained the basics of honed tubing, let’s take a closer look at its manufacturing process, the materials used, and the industries where it's most commonly applied.

Honed tubing is typically made from Cold Drawn Seamless (CDS) or Drawn Over Mandrel (DOM) steel. The honing process removes material from the inner surface to ensure tight tolerances and a polished finish. These tubes are used extensively in industries where precision is paramount, such as in hydraulic cylinders and aerospace applications.

How does the honing process improve hydraulic cylinder performance?

Problem: Achieving optimal performance in hydraulic systems depends on finding precision tubing.

Agitation: A rough inner surface can cause friction, leaks, inefficiency, and early wear in hydraulic cylinders.

Solution: Honing guarantees smooth, polished inner surfaces that diminish friction and promote hydraulic cylinder efficiency.

Honing enhances hydraulic cylinder performance by creating a smooth inner surface that minimizes friction, thereby preserving efficient fluid flow. This prevents pressure loss and conserves seal integrity, contributing to the durability and dependability of the overall hydraulic system.

What materials are most commonly used for honed tubes?

Problem: Choosing the right material for honed tubing is critical to ensure toughness and performance in demanding applications.

Agitation: Not all materials are appropriate for honing, and choosing the wrong one can impact performance.

Solution: Steel alloys such as carbon steel, stainless steel, and alloy steel are frequently used for honed tubes, providing the strength and durability required for high-pressure applications.

The most common materials used for honed tubing include carbon steel (such as SAE 1020, SAE 1026, and ST52.3), stainless steel, and alloy steel. These materials offer the necessary strength, wear resistance, and dimensional stability required for high-performance applications in hydraulic cylinders and aerospace components.

Common materials used for honed tubes include carbon steel, stainless steel, and alloy steel. These materials are selected for their durability, strength, and ability to withstand the honing process without compromising the structural integrity of the tube.

Can honed tubes be customized for specific industrial applications?

Problem: Industrial applications often require tubes with specific dimensions and surface finishes to meet operational needs.

Agitation: Standard honed tubes may not be suitable for the unique requirements of certain industries.

Solution: Honed tubes can be customized to meet specific dimensions, materials, and surface finishes, ensuring optimal performance in various applications.

Customization is a key benefit of honed tubing. Manufacturers are able to produce tubes tailored to specific dimensions, materials, and finishes as required by the customer. Whether for hydraulic cylinders, aerospace, or industrial machinery, honed tubes can be customized to ensure peak performance.

Yes, honed tubes can be customized to suit the unique demands of any application. Customization options include the adjustment of dimensions, materials, and surface finishes to match the specific requirements of different industries.

How does the skiving and roller burnishing process differ from honing?

Problem: Skiving, roller burnishing, and honing all represent tubing finishing processes, but the capabilities they offer differ.

Agitation: Understanding the contrasts can help in selecting the most appropriate process for your application.

Solution: While skiving and roller burnishing enhance surface finishes, honing delivers the utmost in dimensional accuracy and smoothness, making it particularly well-suited to high-precision applications.

Skiving and roller burnishing techniques serve as processes for finishing tubes, optimizing surface smoothness. However, they do not provide the same degree of precision regarding dimensional accuracy as honing. Honing, by contrast, represents a more refined process, grinding the inner tube surface to achieve precise measurements and smoothness. This level of precision is especially suitable for use in applications requiring tight tolerances and smooth fluid flow, such as within hydraulic cylinders and aerospace components.

Skiving and roller burnishing improve the surface finish of tubes, but honing offers superior precision through the grinding of the internal diameter to exact measurements. As a result, honing is the preferred method for high-precision applications such as hydraulic cylinders.

Conclusion Paragraph

Honed tubing is a crucial element in numerous industrial applications, renowned for its precision, durability, and adaptability. Through the honing process, these tubes satisfy the exacting demands essential for effective operation within hydraulic and pneumatic systems. Suitable for high-pressure hydraulic systems, automotive components, and aerospace applications, honed tubing delivers the reliability and performance essential for demanding environments.

Selecting the appropriate honed tubing suppliers and making informed decisions regarding dimensions and materials play a significant role in impacting the performance and longevity of hydraulic systems and machinery. Whether seeking DOM honed tubing or honed tubing in nearby locales, prioritizing quality remains imperative to achieve optimal results.