When it comes to hydraulic cylinders, the use of honed tubes plays a crucial role in determining performance and durability. Low-quality tubes can contribute to poor sealing, accelerated wear, and unexpected downtime. In contrast, honed tubes with their smooth surfaces and structural integrity can help in reducing friction loss, providing better sealing, and delivering extended service life, thereby addressing these common challenges.

Importance of Honed Tubes for Hydraulic Cylinder Performance

When it comes to hydraulic cylinders, the use of honed tubes plays a crucial role in determining performance and durability. Low-quality tubes can contribute to poor sealing, accelerated wear, and unexpected downtime. In contrast, honed tubes with their smooth surfaces and structural integrity can help in reducing friction loss, providing better sealing, and delivering extended service life, thereby addressing these common challenges.

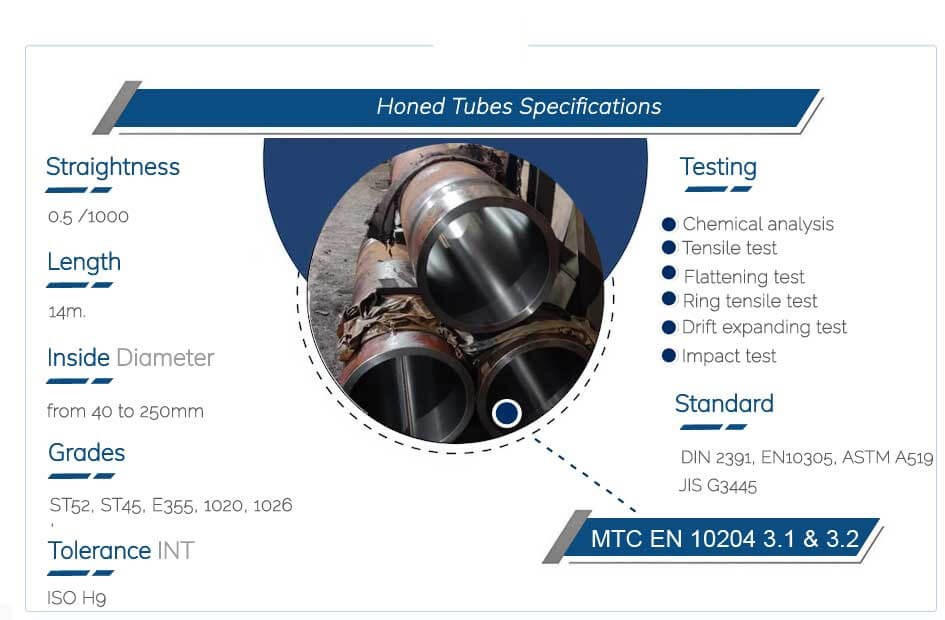

What Are Honed Tubes?

Honed tubes, also known as hydraulic cylinder tubes or honed ID tubing, are precision-engineered seamless steel tubes.

Manufactured through a honing process, they achieve a smooth, uniform internal surface with tight tolerances. This is critical for hydraulic applications that demand reliability and efficiency.

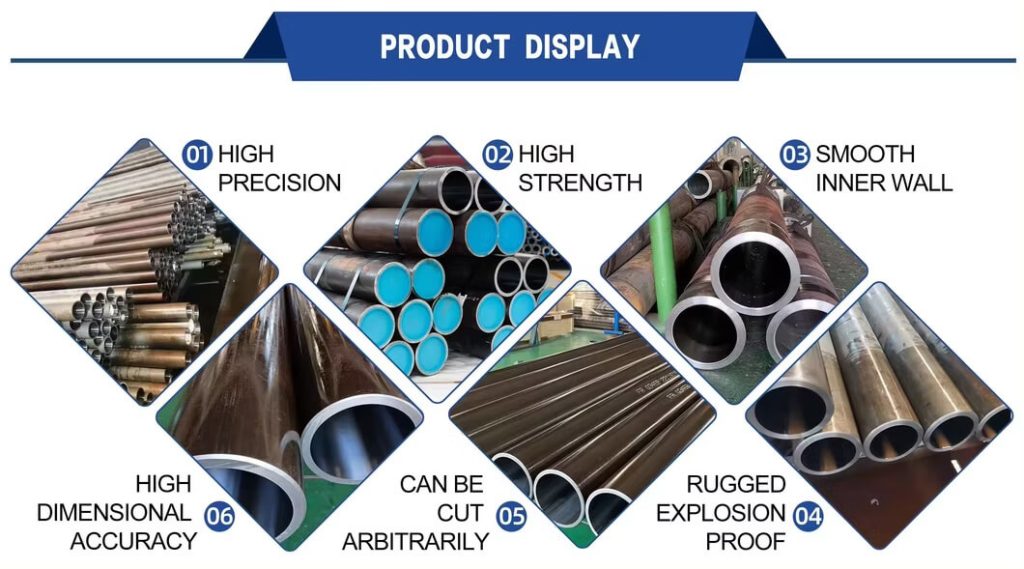

Key Attributes of Honed Tubes:

- Precision: Ensures accurate internal diameters and dimensional accuracy for uniform fluid pressure.

- Durability: Resistant to wear, corrosion, and fatigue, ideal for high-pressure environments.

- Versatility: Available in various sizes and materials (carbon steel, stainless steel) for diverse applications.

Learn more about honed tubes and their manufacturing process.

Discover honed cylinder tube suppliers near you.

Importance of Honed Tubes for Hydraulic Cylinder Performance

The use of honed tubes is crucial to the performance and longevity of hydraulic cylinders. Low-quality tubes can lead to poor sealing, increased wear, and unplanned downtime. High-quality honed tubes with smooth internal surfaces and tight tolerances help reduce friction losses, improve sealing, and increase the service life of components—addressing these common problems of poor quality tubes.

What Materials Are Most Commonly Used for Honed Tubes in Hydraulic Cylinders?

Selecting the appropriate material is critical for achieving optimal performance in hydraulic systems.

The most widely used materials are carbon steel, stainless steel, and alloy steel, each offering various degrees of strength, corrosion resistance, and adaptability.

Material Highlights:

- Carbon Steel: Economical and durable, suitable for general applications.

- Stainless Steel: Exceptional corrosion resistance; ideally suited for harsh environments.

Compare honed tube materials.

Find heavy-duty honed tubes for sale.

What are the main advantages of using honed tubes in high-pressure hydraulic systems?

High-pressure systems require flawless components to ensure safety and efficiency.

Honed tubes can handle the pressure due to their smooth surfaces, their ability to hold seals, and their strength to withstand stress.

Main Benefits:

- They hold seals better and longer.

- They can handle high-pressure applications with ease.

Read the article.

Find a supplier of hydraulic cylinder honed tube.

What are the main uses of honed tubes in high-pressure hydraulic systems?

High-pressure systems require excellent components for safety and efficiency.

Honed tubes can handle the pressure with ease because of their smooth surface, their ability to hold seals, and their innate strength to withstand the stress.

Main Benefits:

- They hold seals better and longer.

- They can handle high-pressure applications without any issues.

Read the article.

Find a supplier of hydraulic cylinder honed tube.

What Industries Benefit Most from Honed Tubes in Hydraulic Systems?

Honed tubes are critical in industries that require reliability and precision.

They are key in ensuring reliable, smooth operation and increased efficiency.

Construction: Use for excavator, loader hydraulic systems requiring precise power transfer.

Automotive: Utilized in braking systems for reliable high-pressure performance.

Aerospace: Lightweight, high pressure components for aircraft hydraulics.

Explore Industries that Use Honed Tubes

Check out honed tubes for hydraulic cylinders.

In Conclusion

Honed tubes are vital components in hydraulic systems due to their superior surface finish, enhanced sealing capabilities, increased durability, and precision engineering. These attributes make them indispensable for various industrial applications, from heavy machinery to aerospace. By investing in high-quality honed tubes, manufacturers can ensure efficient operation, reduced maintenance costs, and long-lasting performance.