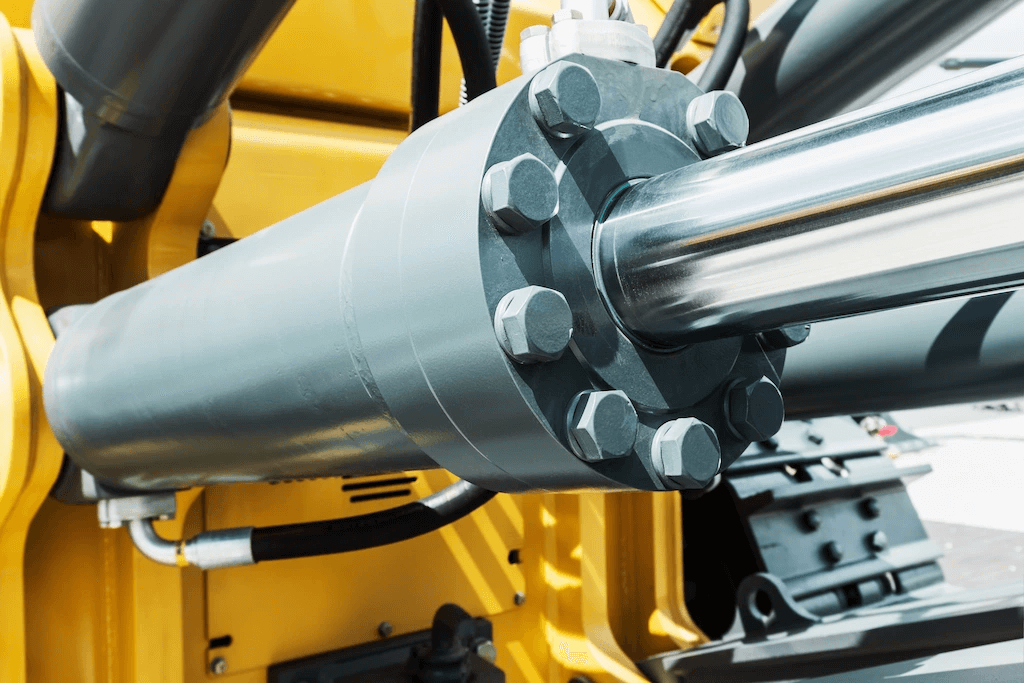

Honed tubes play a crucial role in the efficient and durable performance of construction equipment by providing the precision and strength required for hydraulic and pneumatic systems. Their smooth internal surface and high-quality construction make them an essential component in modern machinery.

In construction machinery, honed tubes are essential for their implementation in hydraulic systems. The polished interiors reduce friction and improve seal compatibility, ensuring efficient and reliable movement, making them ideal for heavy-duty applications across industrial equipment.

Learn more about honed tube properties and uses.

Explore honed tube specifications for hydraulic equipment.

The characteristics and applications of honed tubes in construction equipment underscore their significance in numerous industrial sectors that support the efficiency of hydraulic and pneumatic systems.

1. What is the Use of Honed Tubes?

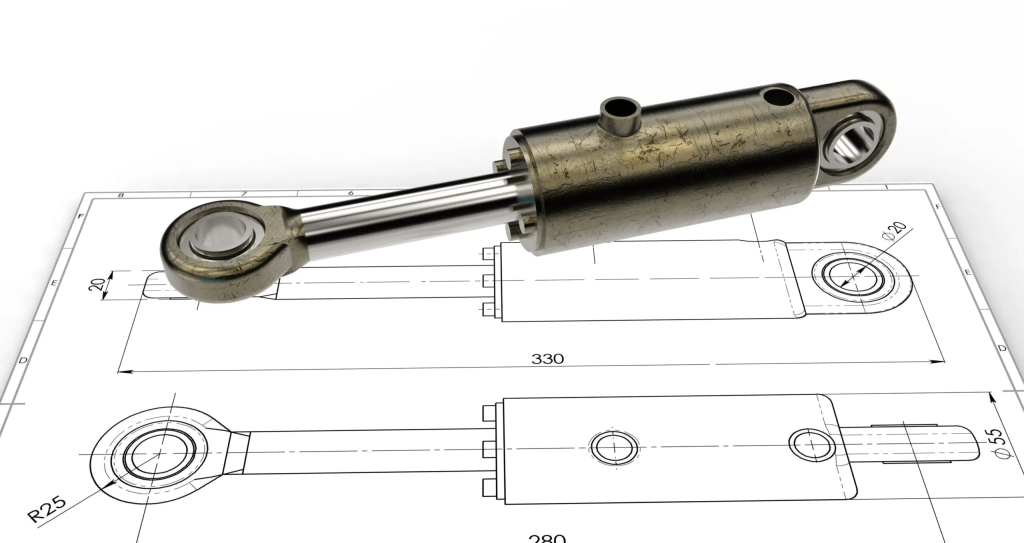

Honed tubes are precision steel tubes commonly used in hydraulic cylinders across a variety of industries including construction, agriculture, and manufacturing. With their ultra-smooth inner surface, honed tubes minimize friction, ensuring efficient fluid transfer and supporting precision operations in critical applications such as pneumatic and hydraulic cylinders as well as in automotive systems.

Snippet: Honed tubes play a pivotal role in enhancing the efficiency and durability of hydraulic systems, making them indispensable components in construction and industrial machinery.

Read more about honed tubes for industrial use

Explore honed tube solutions for hydraulic systems

2. What is Pipe Honing?

Pipe honing is a specialized machining process that creates a smooth interior surface on steel tubes through the use of abrasive stones or honing tools to polish the inner walls. This precision finish enhances fluid dynamics, reduces wear, and assures compatibility with seals, which is crucial for hydraulic systems in applications such as construction and heavy machinery.

Snippet: Honing yields an ultra-smooth interior, allowing hydraulic systems within construction equipment to function with minimal resistance, thereby extending the life of equipment components.

Delve deeper into the pipe honing process.

Discover insights into honed tube finishing for hydraulic applications.

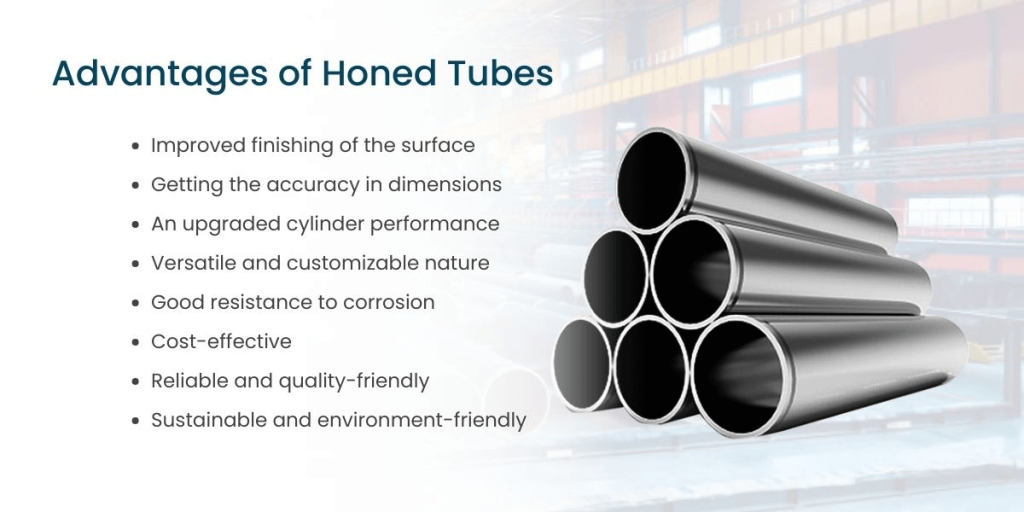

3. What are the Main Benefits of Using Honed Tubes in Construction Equipment?

Utilizing honed tubes offers several key advantages, including improved durability, reduced maintenance costs, and enhanced equipment efficiency. Their meticulously engineered inner surface reduces friction and facilitates proficient movement within hydraulic cylinders, making honed tubes exceptionally well-suited for the demanding high-pressure environments of construction equipment and industrial machinery.

Snippet: Honed tubes play a pivotal role in reducing maintenance costs and increasing efficiency, making them highly advantageous for applications involving construction and heavy-duty machinery.

Explore additional benefits of honed tubes in construction

Observe how honed tubes are beneficial for supporting heavy-duty equipment

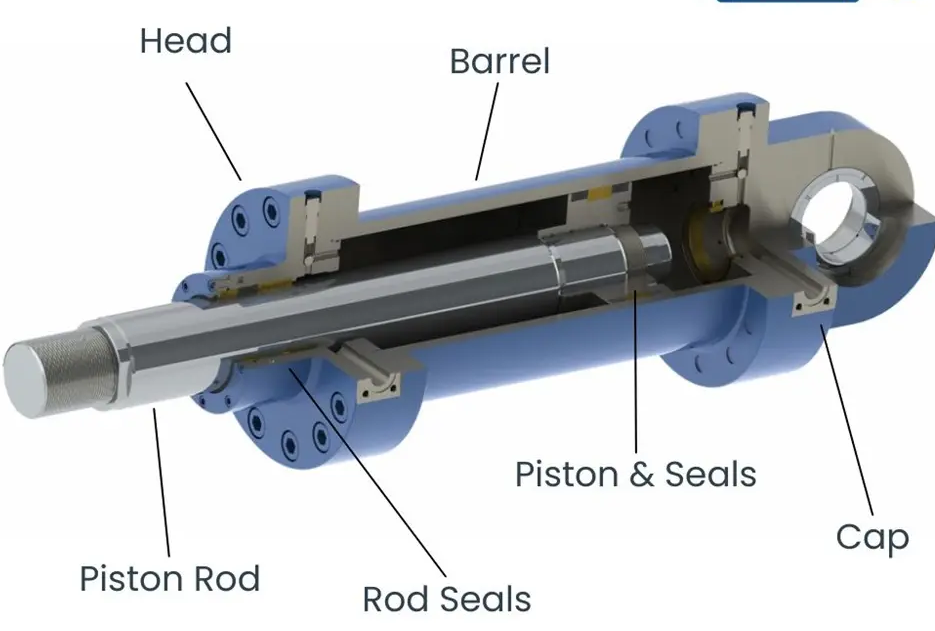

4. How Does the Honing Process Improve the Performance of Hydraulic Cylinders?

The honing process plays a significant role in improving the performance of hydraulic cylinders by enhancing the tube’s smoothness and uniformity. This process minimizes internal friction and improves seal integrity, promoting efficient fluid dynamics within hydraulic cylinders, which are essential components in construction and industrial equipment.

Snippet: Honed tubes elevate hydraulic cylinder performance, ensuring reliable and smooth operation within construction machinery and industrial applications.

Learn more about the impact of honing on hydraulic systems

Discover how honed tubes enhance hydraulic performance

5. What Materials are Most Commonly Used for Honed Tubes in Construction Equipment?

Honed tubes are commonly crafted from robust materials such as Cold Drawn Seamless (CDS) and Drawn Over Mandrel (DOM) steel to withstand the demanding exigency of hydraulic systems in construction. These materials offer exceptional strength, wear resistance, and accuracy, rendering them ideal for employment within hydraulic and pneumatic cylinders serving in these applications.

Snippet: The prevalent use of CDS and DOM steels in the manufacture of honed tubes underscores their ability to deliver both strength and precision, aptly suited for construction machinery and industrial applications.

Learn more about honed tube materials

Explore the variety of material options available for honed tubes

6. Can Honed Tubes Be Customized for Specific Construction Equipment Applications?

Honed tubes can be tailored to satisfy particular demands within construction equipment, incorporating adjustments in diameter, wall thickness, and length. The customization ensures precise compliance with the requirements of hydraulic cylinders, enhancing performance and reliability for demanding operations.

Snippet: Custom honed tubes contribute flexibility, accommodating the need for optimized hydraulic capabilities across diverse construction applications.

Explore personalized honed tube solutions for construction applications.

Discover options for custom honed tubes.

7. How Does the Size of a Honed Tube Affect its Performance in Hydraulic Systems?

The size of a honed tube, notably its diameter and wall thickness, significantly impacts hydraulic pressure and system performance. Properly proportioned tubes facilitate the reliable conveyance of fluid and minimize pressure fluctuations, both of which are integral to ensuring seamless operation in the hydraulic systems of construction equipment.

Snippet: Appropriate honed tube dimensioning supports consistent pressure management and hydraulic efficacy, both critical for construction and industrial applications.

Discover the significance of honed tube sizing

Explore honed tube dimensions for optimized performance in hydraulic systems

Conclusion

Honed tubes provide the durability, precision, and efficiency that modern construction and industrial equipment require. By enhancing hydraulic and pneumatic systems' performance, they support machinery's long-term reliability and functionality, making them indispensable in various applications.

| Aspect | Details |

|---|---|

| Material Composition | Typically made from Cold Drawn Seamless (CDS) or Drawn Over Mandrel (DOM) steel for high strength and durability. |

| Surface Finish | Achieved through honing or skiving and roller burnishing, providing an ultra-smooth internal surface that minimizes friction and wear. |

| Dimensions | Available in diameters ranging from 1 inch (25.4 mm) to over 10 inches (254 mm); custom sizes available for specific applications. |

| Applications | Used in hydraulic and pneumatic systems in construction machinery, industrial equipment, automotive components, and precision machinery. |

| Main Benefits | Enhanced performance, reduced maintenance, high durability, and excellent compatibility with hydraulic seals for improved system efficiency. |

| Customization | Honed tubes can be customized in terms of diameter, wall thickness, and length to fit specific equipment requirements. |

| Performance Impact | Proper sizing and smooth finish allow for optimal fluid dynamics, pressure stability, and efficient operation in hydraulic systems, especially under high pressure. |