Machine tools face challenges such as wear, reduced accuracy, and increased maintenance costs. These challenges can result in delays and inefficiencies, increased costs, and decreased production capacity. Precision honed tubes can help solve these problems with high performance, durability, and precision for hydraulic and machine tool applications.

Precision honed tubes are a must-have for high-performance machinery, especially in hydraulic systems. They provide increased precision, durability, and smooth internal surfaces with reduced friction and lower maintenance costs, making them well-suited for machine tools and other demanding industrial applications.

We will explore the manufacturing process, key properties, benefits, and applications discovering why precision honed tubes are indispensable in the automotive, heavy machinery, and hydraulic system industries.

What Are Precision Honed Tubes?

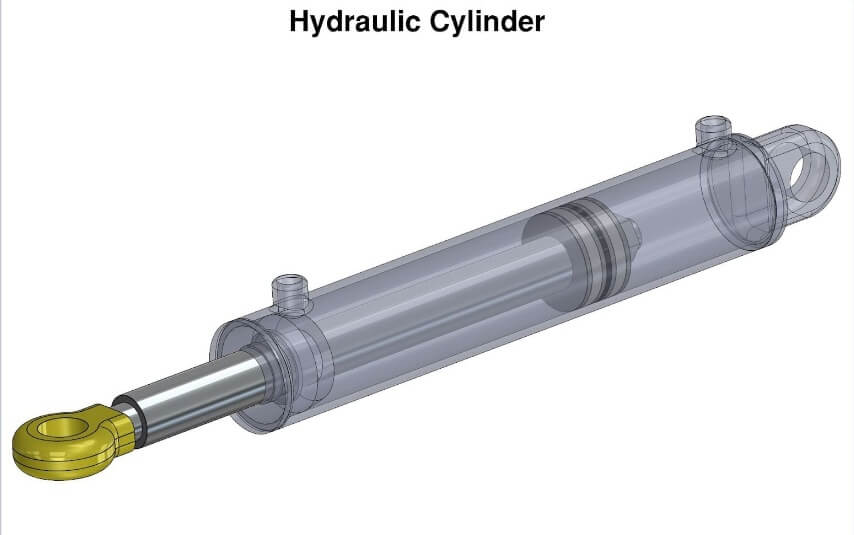

Precision honed tubes are seamless steel tubes that have undergone a specialized honing process to refine their internal surface. This process eliminates imperfections and yields smooth, highly accurate inner diameters, making them ideal for hydraulic cylinders and other applications requiring tight tolerances and consistent performance.

The honing process refines the internal surface to ensure minimal friction and maximum efficiency, which is crucial for high-performance machinery such as hydraulic cylinders and precision machining equipment.

[Learn more about the honing process here.]

[Discover more about hydraulic system components.]()

Manufacturing Process of Precision Honed Tubes

The manufacturing process of precision honed tubes comprises several essential stages:

- Material Selection: High-quality steel is selected for its strength and durability, ensuring that the tube can withstand the demands of high-pressure systems and heavy machinery.

- Tube Formation: The steel is cut to the desired length and rolled into seamless tubes, creating the foundation for the honing process.

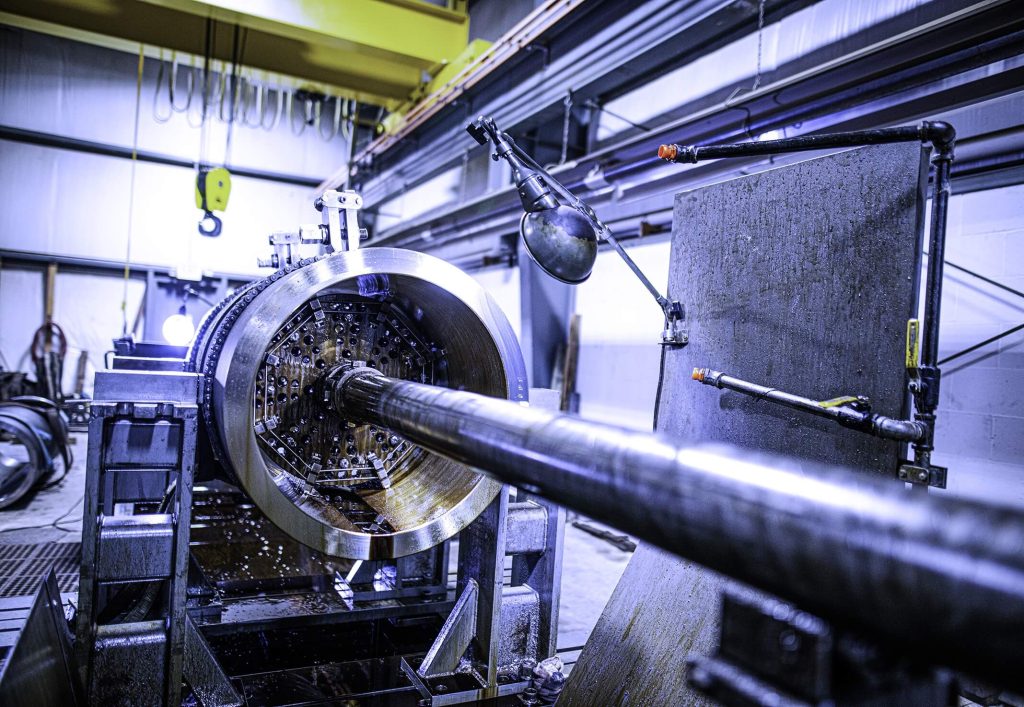

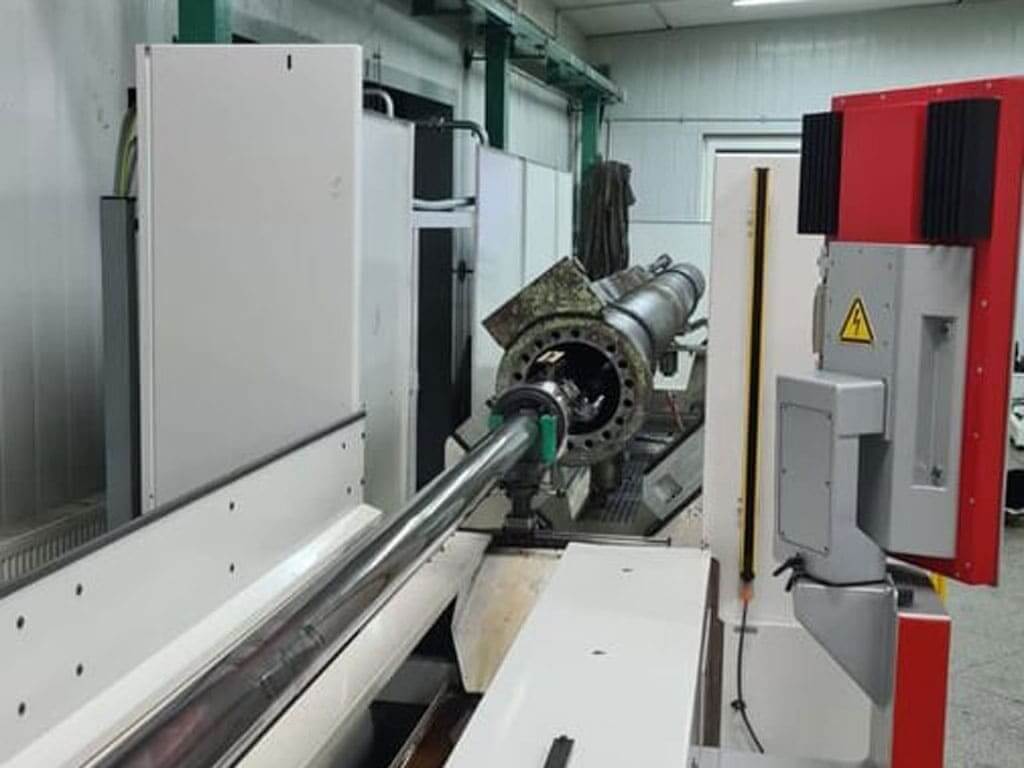

- Honing Process: A specialized tube honing machine refines the internal surface of the tube. This step ensures the precise adjustment of the tube’s inner diameter to achieve tight tolerances and a smooth finish.

- Finishing: Additional treatments such as phosphate coating may be applied to improve the tube’s corrosion resistance and extend its service life.

The precision honing process guarantees the smoothness of the internal surface, rendering these tubes well-suited for systems requiring minimal friction and high performance, such as hydraulic systems

[Learn more about precision honing technology.]

[Check out how tube honing machines work.]

Properties of Precision Honed Tubes

Precision honed tubes are esteemed for their high precision, strength, and durability, deemed essential for their diverse range of applications:

- High Precision: The honing process ensures highly accurate inner diameters, often within tolerances such as H7 or equivalent, paramount for hydraulic and machine tool systems.

- Strength and Durability: Composed of sturdy materials, honed tubes can endure high-pressure environments and extreme operational conditions, ensuring exceptional long-term use.

- Smooth Finish: The honed inner surface minimizes friction and wear, enhancing the efficiency of hydraulic systems and other machinery.

- Corrosion Resistance: Many honed tubes receive treatments to augment resistance against corrosion, enabling reliable operation in harsh industrial settings.

The fusion of precision and durability renders honed tubes an optimal solution for heavy-duty machinery, hydraulic cylinders, and pneumatic cylinders, necessitating high reliability.

[Explore the materials used in honed tube manufacturing.]

[Find out more about corrosion resistance in honed tubes.]

Benefits of Precision Honed Tubes

The benefits of utilizing precision honed tubes extend beyond their smooth internal surface, providing:

- Enhanced Performance: The smooth surface diminishes friction, resulting in amplified efficiency and decreased energy consumption in components like hydraulic cylinders and precision machining.

- Elevated durability: The construction from high-quality steel and the processes of honing ensure these tubes can withstand rigorous conditions, reducing the need for frequent replacements.

- Decreased maintenance: The durability and precision of their dimensions reduce maintenance requirements, lowering downtime and repair expenses.

- Cost efficiency: The extended lifespan of honed tubes offers a cost-effective solution, delivering significant value by reducing the frequency of replacements and repairs.

By curtailing friction and wear, honed tubes help extend the operational life of machinery and hydraulic systems, contributing to reduced overall maintenance costs.

[Learn how honing improves machine tool performance.]

[See how honed tubes reduce maintenance costs in hydraulic systems.]

Common Applications of Precision Honed Tubes

Precision honed tubes find use across diverse industries and applications, including:

- Hydraulic Cylinders: Widely employed in heavy machinery such as excavators, cranes, and construction equipment to establish dependable hydraulic systems.

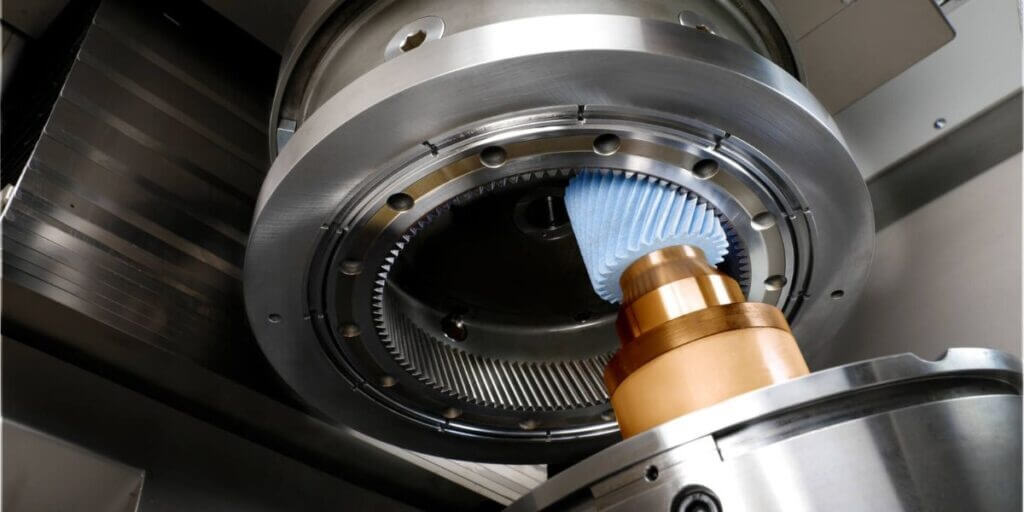

- Precision Machining: Utilized in lathes and milling machines where a need for high precision exists to achieve accurate and consistent outcomes.

- Automotive Industry: Prevalent in hydraulic systems for brakes, suspensions, and steering mechanisms, where precision and durability are paramount.

- Pneumatic Cylinders: Honed tubes are suitable for applications involving compressed air to induce movement within machinery and automation systems.

Across construction, automotive, and precision machining sectors, honed tubes contribute significantly to ensuring the efficient operation of hydraulic and pneumatic systems.

[Explore hydraulic tube applications in the automotive industry.]

[Check out the role of honed tubes in precision machining.]

Conclusion Paragraph:

Precision honed tubes are essential components for improving the performance and longevity of machine tools, hydraulic cylinders, and other critical machinery. Their ability to reduce friction, increase efficiency, and minimize maintenance requirements makes them invaluable in a variety of industrial applications. As technology advances, the demand for these high-quality components continues to rise, further underscoring their importance in modern manufacturing processes.