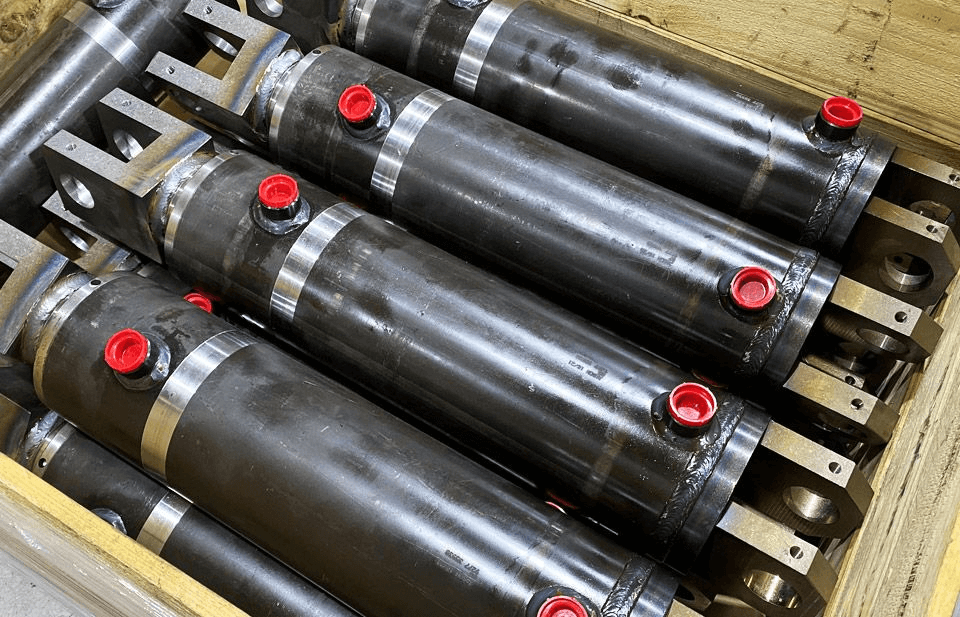

Seamless Tubes for Hydraulic Cylinder Applications

Seamless tubes are indispensable components within hydraulic cylinders, renowned for providing superior strength and durability in high-pressure applications. Renowned for their precision dimensions and consistent mechanical properties, seamless tubes represent the primary choice of material for industries reliant on steadfast, high-performance hydraulic systems. These essential components are essential within industries such as construction, automotive, and manufacturing, serving as a backbone for critical machinery operations.

Advantages of Seamless Tubes

Higher Structural Integrity:

The absence of welded seams is the primary advantage of seamless tubes, greatly enhancing their strength and pressure resistance, particularly vital for hydraulic cylinders operating under high pressure. Seamless tubes can withstand extreme stress without compromising system safety or reliability.

Enhanced Mechanical Properties:

The manufacturing process for seamless tubes yields superior mechanical properties, including improved fatigue resistance and toughness, rendering them ideal for rugged environments demanding durability and reliability, such as in heavy machinery, automotive systems, and renewable energy equipment.

Precision and Reliability:

Seamless tubes can be produced with tight tolerances, ensuring a precise fit within hydraulic components. This high level of precision minimizes the risk of leaks, enhances overall system reliability, and ensures optimal efficiency and safety in hydraulic cylinder operation.

Versatility in Applications:

Seamless tubes are essential for various hydraulic cylinder components, including barrels and piston rods. They can be customized for specific applications, such as in telescopic cylinders used in cranes, excavators, and other earth-moving machinery. Their versatility equips them to meet the diverse demands of industries where hydraulic systems are critical to effective operations.

Types of Seamless Tubes for Hydraulic Cylinders

Cold Drawn Seamless Tubes

Processed at room temperature, cold drawn seamless tubes are characterized by a smooth surface finish and enhanced dimensional accuracy. Their superior strength properties make them a popular choice for hydraulic cylinders, capable of withstanding high-pressure conditions without deformation.

Hot Rolled Seamless Tubes

While less common in high-performance applications, hot rolled seamless tubes remain suitable for applications not exposed to extreme conditions. Produced at higher temperatures, these tubes are utilized in environments with less stringent performance requirements.

Honed Tubes

Also referred to as "ready to hone," honed tubes undergo additional processing to achieve a smooth inner surface through honing techniques. This process is particularly advantageous for hydraulic cylinders that demand high precision and minimal friction. It ensures compliance with strict dimensional and surface finish requirements for critical applications.

Specifications and Standards

Seamless tubes used in hydraulic applications are manufactured in compliance with various international standards to ensure they possess the required dimensional accuracy and mechanical properties. Notable standards include:

- EN 10305-1 and DIN 2391: These standards outline the specifications for cold-drawn seamless tubes.

- Outer Diameter (OD) : The outer diameter of these tubes ranges up to 400 mm.

- Wall Thickness (WT) : Typically, the wall thickness varies from 4 mm to 10 mm based on the intended application.

- Steel Grades: Commonly employed steel grades include E355, ST52-3, and other high-strength materials designed to withstand demanding conditions, ensuring the tubes maintain optimal performance under pressure.

Applications of Seamless Tubes in Hydraulic Cylinders

Seamless tubes are essential components in hydraulic cylinders across a diverse range of industries, including:

- Heavy Machinery: In excavators, bulldozers, and similar heavy machinery, seamless tubes play a critical role in hydraulic cylinders requiring exceptional strength and durability.

- Cranes: Hydraulic systems utilized in cranes rely on seamless tubes to facilitate lifting operations, ensuring reliable and efficient operation.

- Automotive Systems: In brake and power steering systems, seamless tubes provide the precision essential for effective performance.

- Renewable Energy Equipment: Hydraulic cylinders integral to wind turbines, as well as solar panel mechanisms, require seamless tubes capable of reliably delivering performance under varying environmental conditions.

Conclusion

In conclusion, seamless tubes are essential to the performance and reliability of hydraulic cylinders across various industries. Their superior mechanical properties, high precision, and adherence to international standards make them the ideal choice for hydraulic applications where performance is critical. Whether for earth-moving machinery, cranes, or renewable energy equipment, seamless tubes provide the structural integrity and reliability needed to ensure safe and efficient hydraulic systems.