Problem: Engineers and manufacturers often struggle to source durable and precise tubing for their hydraulic and pneumatic systems.

Agitation: Without the right materials, these systems suffer from inefficiencies, wear, and potential failures, leading to increased downtime and cost.

Solution: ST52 chrome plated honed tubes provide the strength, precision, and corrosion resistance needed for high-performance industrial applications.

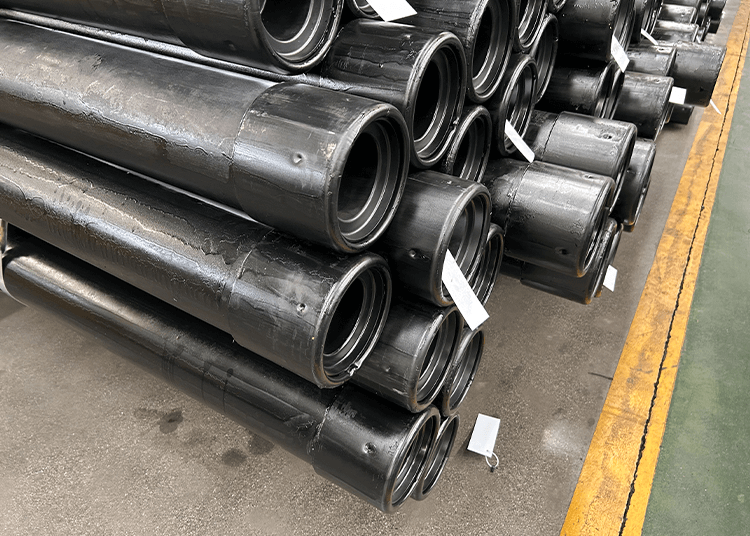

Overview of ST52 Chrome Plated Honed Tubes

ST52 chrome plated honed tubes are specialized steel tubes designed primarily for hydraulic and pneumatic systems. These tubes offer high precision, strength, and durability, making them indispensable in demanding industrial applications.

Material Composition

ST52 is a low-alloy, high-strength steel, known for its excellent machinability and mechanical properties. Its chemical composition typically includes:

- Carbon (C): 0.22 - 0.28%

- Manganese (Mn): 0.60 - 0.90%

- Phosphorus (P): Max 0.010%

- Sulfur (S): Max 0.025%

- Silicon (Si): 0.10 - 0.25%

Mechanical Properties

ST52 steel exhibits impressive mechanical strength:

- Yield Strength: 510-590 MPa

- Tensile Strength: Approximately 85 ksi

- Elongation: 15% (in a 2-inch sample)

These attributes make ST52 an ideal material for high-stress applications in hydraulic and pneumatic systems. ([Learn more about ST52 steel properties](Zuora article link)).

Why Choose ST52 Chrome Plated Honed Tubes Over Regular Steel Tubes?

Problem: Standard steel tubes often lack the precision and durability required for critical applications.

Agitation: This can result in increased maintenance costs, inefficiencies, and potential failures.

Solution: ST52 chrome plated honed tubes, with their superior material composition and production process, provide unmatched performance and longevity.

ST52 Tubes are cold-drawn and honed for precise dimensions and a smooth internal surface finish. This precision reduces friction and improves the performance of hydraulic systems. Additionally, the chrome plating significantly increases their resistance to corrosion and wear, extending their service life even in harsh environments. (Read about the honing process.

Production Process

The production of ST52 chrome plated honed tubes involves several key steps to ensure their quality and durability:

- Seamless Tube Formation: The base material is manufactured using seamless techniques to maintain structural integrity.

- Honing Process: Precision machining is applied to create a smooth internal surface with roughness as low as RA0.1 μm. This is crucial for hydraulic applications where seals and pistons require minimal friction.

- Chrome Plating: A hard chrome layer is added to improve corrosion resistance and wear properties, making these tubes suitable for high-pressure environments.

- Quality Inspection: Rigorous testing and inspection are conducted throughout the production process to meet international standards such as DIN2391, EN10305, and ASTM A519. (Learn about DIN2391 standards.

Common Applications of ST52 Chrome Plated Honed Tubes

ST52 chrome plated honed tubes serve as a valuable resource for numerous machinery and equipment projects across diverse industries, primarily in demanding hydraulic and pneumatic applications. Examples of common uses include:

Hydraulic cylinders: ST52 honed tubes are integral components of hydraulic cylinders, serving as reliable and efficient conveyors for the hydraulic power that moves various hydraulic machinery and tools.

Telescopic cylinders: These engines designed with ST52 chrome plated honed tubes function as prime movers in applications such as cranes, earth-moving machines, and other similar heavy equipment.

Measuring the Geometric Surface Finishes of ST52 Chrome Plated Honed Tubes

In an effort to gauge the geometric surface qualities and the chromium plated products, several primary measuring instruments and techniques are utilized. It encompasses a roughness dimension assessment by using surfometers, microstructure evaluations, RDX solder and Sulphamate nickel layer thickness measurement tools, and examining the coatings' corrosion resistance.

Testing of Hard Chrome Plated Hone Tubes

A variety of testing methodologies are employed to ascertain the robust resistance and durability of hard chrome plated hone tubes, ensuring they adhere to the required quality benchmarks. The procedures may include hydrogen loss, yielding a statistical evaluation of the hardness and layer thicknesses, along with a layer adhesion appraisal and correlative analyses elucidating the tube's fatigue endurance.

International Market Prospects for Hard Chrome Plated Honed Tubes

Many nations across the globe are increasingly recognizing the extensive utility of hard chrome plated honed tubes within diverse manufacturing and infrastructure sectors. Consequently, the tubes are emerging as a sought-after commodity in diverse global markets.

Specifications of ST52 Chrome Plated Honed Tubes

ST52 chrome plated honed tubes are manufactured with tight tolerances to meet diverse industrial needs:

- Internal Diameter (ID): Ranges from 30 mm to 762 mm.

- Length: Available in fixed or random lengths up to 15 meters.

- Diameter Accuracy: Conforms to H7, H8, or H9 tolerances depending on requirements.

These precise specifications ensure compatibility with a wide range of hydraulic and pneumatic systems. (Learn about tolerance levels.

Benefits of Using ST52 Chrome Plated Honed Tubes in Hydraulic Cylinders

Problem: Hydraulic cylinders require components that withstand high pressures and ensure smooth operation.

Agitation: Inferior materials can lead to leaks, inefficiencies, and system failures.

Solution: ST52 chrome plated honed tubes provide the precision, durability, and corrosion resistance essential for hydraulic cylinder performance.

The chrome plating reduces friction and wear on seals and pistons, while the honed surface ensures efficient movement of hydraulic fluids. These features contribute to reduced maintenance costs and increased reliability. (See benefits of chrome plating.

Can ST52 Chrome Plated Honed Tubes Be Customized?

Problem: Standard tubing dimensions may not meet the specific needs of specialized systems.

Agitation: This can lead to design constraints and inefficiencies.

Solution: ST52 chrome plated honed tubes are highly customizable, making them suitable for diverse applications.

Manufacturers offer customization options, including diameter, length, and wall thickness, ensuring compatibility with unique system requirements. Custom designs are particularly beneficial for specialized hydraulic and pneumatic equipment. (Explore custom tubing solutions).

Typical Lead Time for ST52 Chrome Plated Honed Tubes

The lead time for ST52 chrome plated honed tubes varies depending on customization and order volume:

- Standard Orders: Typically 3 to 6 weeks.

- Custom Orders: May take up to 12 weeks due to the precision involved.

It’s recommended to consult suppliers early to align production schedules with project timelines. (Check production timelines.

Conclusion

ST52 chrome plated honed tubes combine the strength of ST52 steel with the precision of honing and durability of chrome plating, making them ideal for high-stress, high-precision applications. Their customizable specifications and superior mechanical properties ensure compatibility with various industrial systems, from hydraulic cylinders to manufacturing equipment. For industries seeking reliability and performance, ST52 chrome plated honed tubes are the ultimate solution.