The Importance of Honed Hydraulic Cylinder Tubes and Their Materials

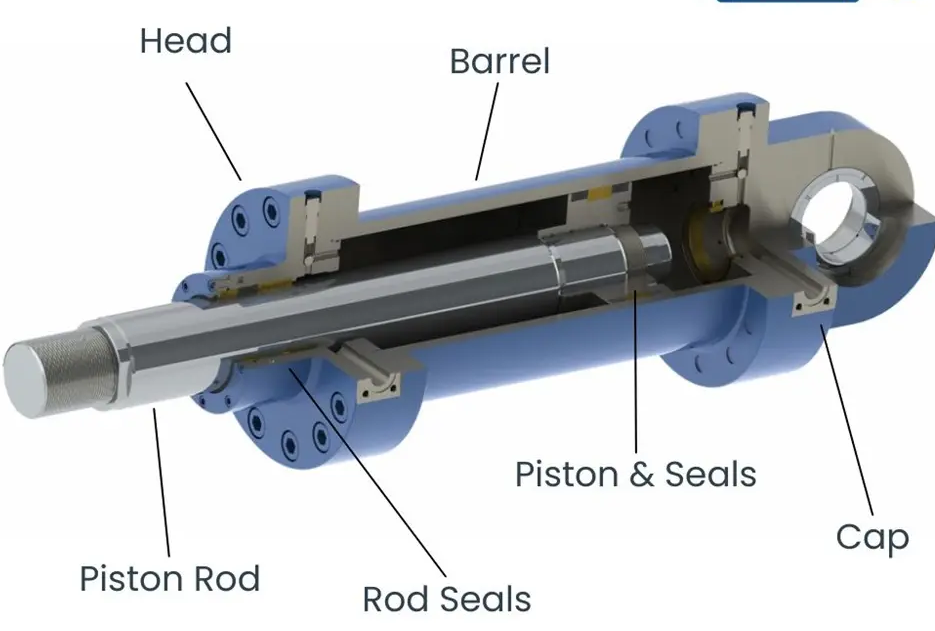

1.Efficient hydraulic systems rely on smooth and robust cylinder tubes. Failure to select appropriate materials and hone the tubes may result in wear and tear on hydraulic cylinders, leading to costly repairs and compromised performance. Accordingly, the selection of suitable materials and tube honing is pivotal for the longevity and efficacy of hydraulic systems.

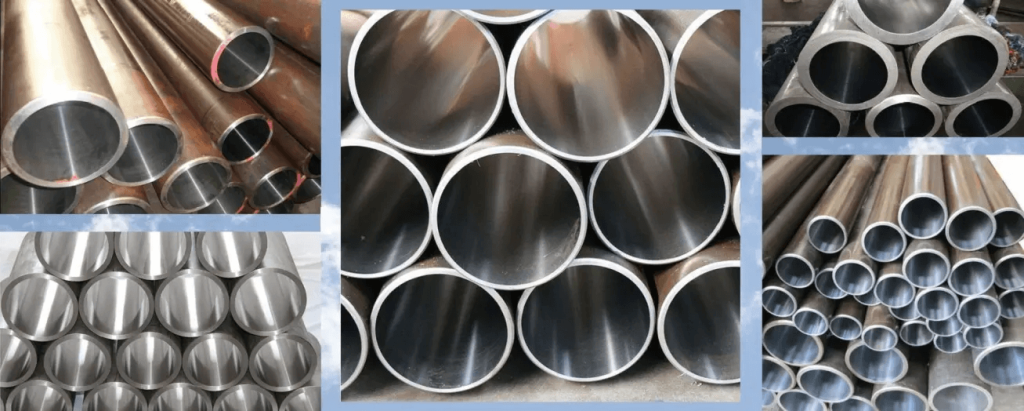

2.Honed hydraulic cylinder tubes are typically crafted from carbon steel, stainless steel, and aluminum. Each material is selected for particular applications based on characteristics such as durability, resistance to corrosion, and weight. The honing process is instrumental in creating a smooth, meticulously crafted interior surface, a critical factor in minimizing friction within hydraulic systems. Robust comprehension of the distinctiveness of various materials and their respective applications is invaluable for informed decision-making.

3.Having acknowledged the importance of honed hydraulic cylinder tubes, it is imperative to consider the materials utilized in the production of these tubes and the role honing plays in optimizing their performance within hydraulic systems.

4.Question 1: What is the material of honed tube?

Sub Leading Paragraph:Honed hydraulic cylinder tubes are frequently crafted from materials such as carbon steel, stainless steel, and, in some cases, aluminum. Selection of these materials is based on their robustness, corrosion resistance, and suitability for operation in high-pressure environments.

Sub Snippet Paragraph:Carbon steel is notable for its exceptional durability and cost-effectiveness, while stainless steel is highly regarded for applications demanding corrosion resistance. Aluminum, due to its lightweight properties, is particularly well-suited for industries that require components with reduced weight.

For more information about honed hydraulic cylinder tubes of various materials, check out this PDF guide on material properties.

If you need honed hydraulic cylinder tubes of various materials near you, explore local suppliers on this page.

Question 2: What material is used for hydraulic cylinder tubes?

Sub Leading Paragraph:Common materials for hydraulic cylinder tubes include carbon steel and stainless steel. These materials are chosen for their strength and resistance to corrosion, and the final selection depends on the operating conditions.

Sub Snippet Paragraph:Carbon steel is chosen for its strength and cost-efficiency, making it suitable for use in high-pressure applications. Stainless steel, on the other hand, is often chosen for its corrosion resistance, ensuring long-term performance in harsh environments.

Learn more about honed hydraulic cylinder tubes for hydraulic systems from this standard size PDF guide.

Need to compare prices for honed hydraulic cylinder tubes? Check out this pricing resource.

Question 3: What is suitable to hone tubing?

Sub Leading Paragraph: Tubing made from durable materials like carbon steel and stainless steel is suitable for honing, as these materials can withstand the precision process required to create a smooth interior surface.

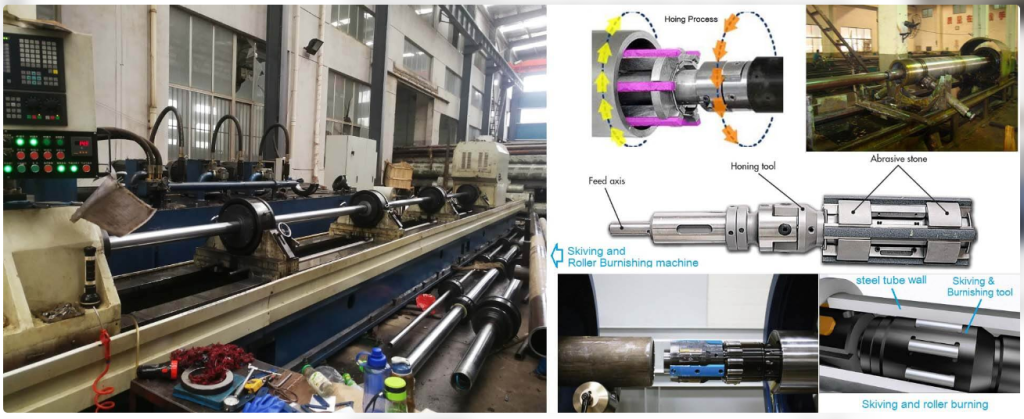

Sub Snippet Paragraph: The honing process removes small imperfections inside the tube, ensuring minimal friction within the hydraulic cylinder. This smooth finish extends the lifespan and enhances the performance of hydraulic systems.

For specific honed tube sizes for hydraulic cylinders, refer to this size chart.

If you’re searching for honed tubing suppliers near you, this supplier directory can help.

Question 4: Should a hydraulic cylinder be honed?

Sub Leading Paragraph: Yes, honing is a crucial process for hydraulic cylinders. The smooth surface created by honing reduces friction between the cylinder components, improving efficiency and longevity.

Sub Snippet Paragraph: Without honing, the increased friction in hydraulic cylinders can lead to inefficiencies, overheating, and faster wear of components. Honing ensures a precise fit and smoother operation.

Learn about honed hydraulic cylinder tubes and the advantages of honing from this informational guide.

Interested in learning more about the benefits of honed tubing for hydraulic systems? This resource has detailed insights.

5.Conclusion Paragraph:In conclusion, selecting the right material for honed hydraulic cylinder tubes—whether carbon steel, stainless steel, or aluminum—and ensuring they are properly honed are critical steps in optimizing hydraulic system performance. The honing process guarantees a smooth surface, reducing friction and prolonging the life of hydraulic components.