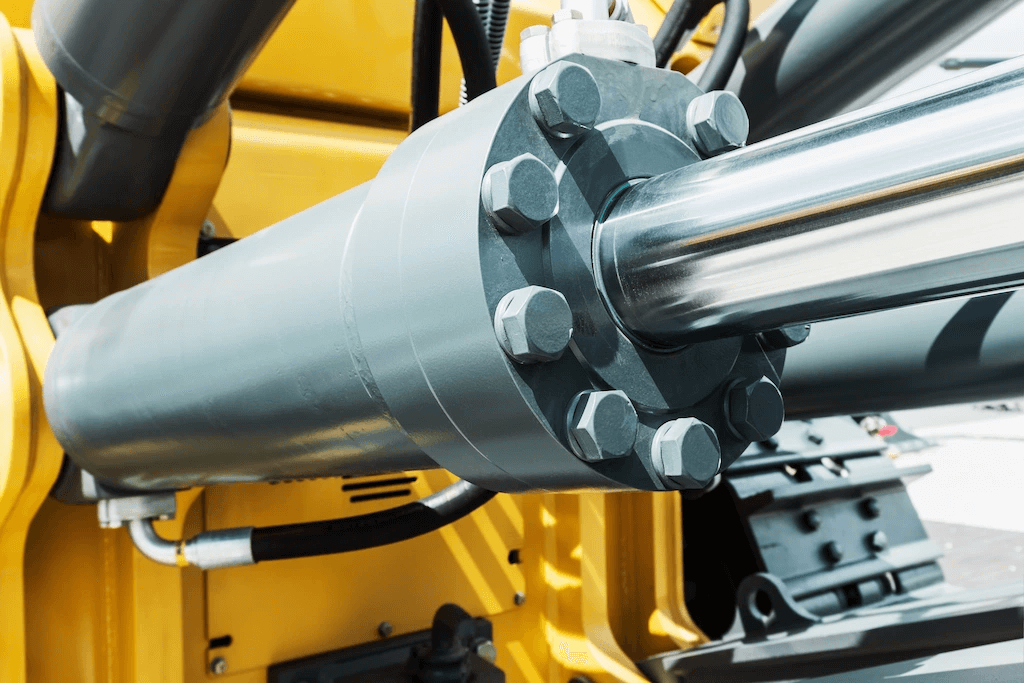

Hydraulic systems require precision and durability, and concerns often arise regarding the quality and longevity of cylinder tubes. Honed hydraulic cylinder seamless steel tubes offer an optimal solution, presenting superior strength and a smooth interior surface to ensure consistent high-pressure performance.

The definition effectively communicates the characteristics of the honed hydraulic cylinder seamless steel tube, emphasizing its precision engineering, smooth interior surface, and resilience to high pressures in hydraulic systems.

Learn more about the benefits of honed tubes

Understanding hydraulic cylinder materials

Understanding the construction, material, and applications of these tubes across industries is crucial for comprehending their significance.

What is a Honed Tube?

Problem: Customers often question, “What is a honed tube?” as they seek clarity regarding its role in hydraulic systems.

Agitate: Lack of understanding about honing jeopardizes the selection of subpar materials for high-pressure applications.

Solution: A honed tube is a precision-engineered steel pipe featuring a meticulously polished inner surface designed for use in hydraulic cylinders. The honing process eliminates material from within the tube to create a flawless finish, reducing friction and ensuring superior sealing.

For hydraulic systems, particularly those utilizing a honed stainless steel tube, a precision honed tube is essential for seamless operation. Its exact measurements and standardized quality are crucial, and documents such as a Honed Tube standard sizes PDF are invaluable resources for determining the appropriate specification.

Learn about honing standards

Explore standard sizes for honed tubes

Should a Hydraulic Cylinder Be Honed?

Problem: Many individuals wonder whether the interior of a hydraulic cylinder requires honing.

Agitate: Neglecting to hone the cylinder might result in inadequate sealing, diminished operational efficiency, and accelerated wear.

Solution: It is advisable to hone hydraulic cylinders to establish a smooth interior surface, minimizing friction and wear. The honing process guarantees that the hydraulic cylinder tube has a precise finish, thereby enhancing the performance and longevity of the hydraulic system.

Hydraulic systems integrated with a honed tube for hydraulic cylinders experience reduced operational wear and heightened efficiency thanks to the honing process, which ensures the development of a perfectly smooth internal surface.

Why honing is crucial for hydraulic cylinders

Best practices for hydraulic cylinder maintenance

What Does Seamless Steel Tubes Mean?

Problem: The distinction between seamless and welded tubes is an area of confusion for many buyers.

Agitate: The selection of an inappropriate tube type may compromise the integrity of a system, particularly under high pressure.

Solution: Seamless steel tubes, unlike their welded counterparts, are produced without joints or seams, thus offering superior strength and durability. In hydraulic systems, seamless honed tubes are the preferred choice due to their capacity to withstand high pressures without the potential risks associated with seam failure.

The absence of seams in the construction ensures the absence of weak points in the honed pipes, rendering them optimal for demanding applications in engineering and hydraulic systems.

Seamless vs welded tubes: key differences

Why seamless tubes are preferred in hydraulic systems

Are Hydraulic Tubes Seamless?

Problem: Questions may arise about the necessity of seamless hydraulic tubes for optimal performance.\

Agitate: Non-seamless hydraulic tubes are susceptible to leaks or ruptures under high pressure, presenting potential hazards to system safety.\

Solution: Yes, the majority of hydraulic tubes are seamless because this construction eliminates the potential for weak points, ensuring enhanced durability and strength. Numerous suppliers of honed cylinder tubes offer both standard and custom seamless options tailored for hydraulic applications. The dimensions provided in the honed tube size chart enable the accurate specification of sizes for diverse hydraulic requirements, guaranteeing optimal performance and prolonged service life.

Explore why seamless tubes are critical in hydraulics

Check out standard hydraulic tube sizes

Conclusion

The summary emphasizes the importance of honed hydraulic cylinder seamless steel tubes for ensuring durability, precision, and high performance in hydraulic systems. Understanding their significance and selecting the appropriate specifications can substantially enhance operational efficiency.

Choosing the best hydraulic cylinder tubes

Find the best suppliers for honed tubes