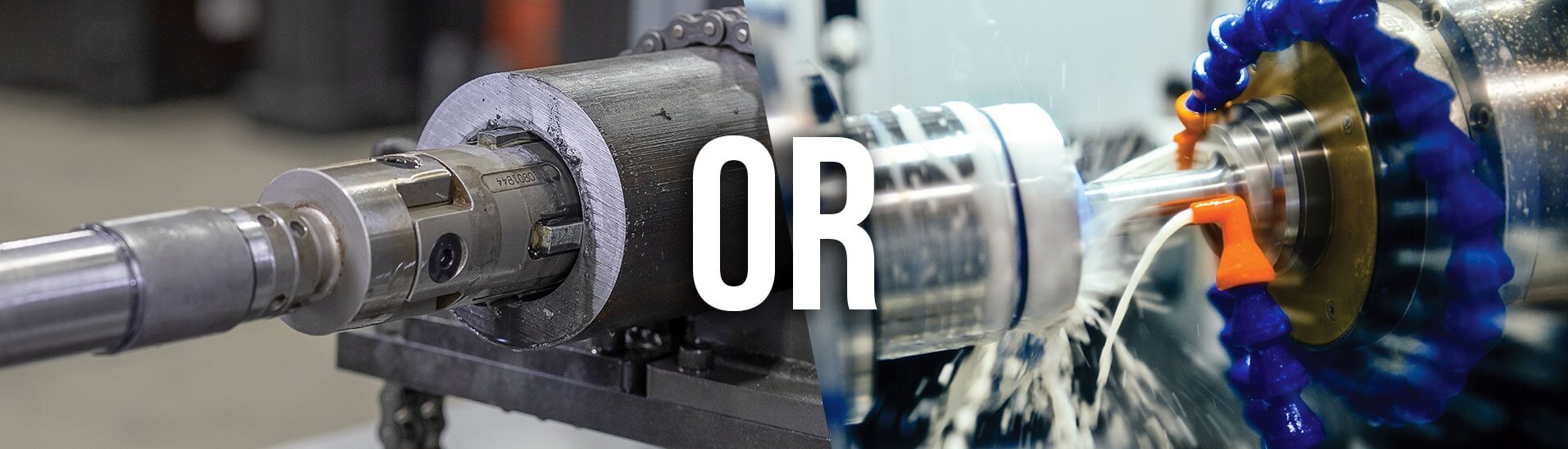

Precision steel tubes offer unmatched accuracy and strength for machinery applications. Let’s explore their features and advantages.

Precision steel tubes are seamless or welded tubes known for their dimensional accuracy, strength, and versatility in machinery.

Curious to know more about their qualities? Keep reading.

What is a precision steel tube?

Precision steel tubes are designed for high accuracy and durability.

A precision steel tube is a seamless or welded tube with tight dimensional tolerances and smooth finishes, ideal for mechanical uses What is a precision steel tube?[^1].

Dive Deeper: Features of Precision Steel Tubes

Precision steel tubes are widely used in industries where exact dimensions and high-quality materials are critical.

Key Characteristics

| Feature | Benefit |

|---|---|

| Tight Tolerances | Ensures accuracy in assemblies |

| Smooth Inner Surface | Reduces wear in moving components |

| High Strength | Supports demanding applications |

Explore the features of precision steel tubes[^2] to understand their industrial applications.

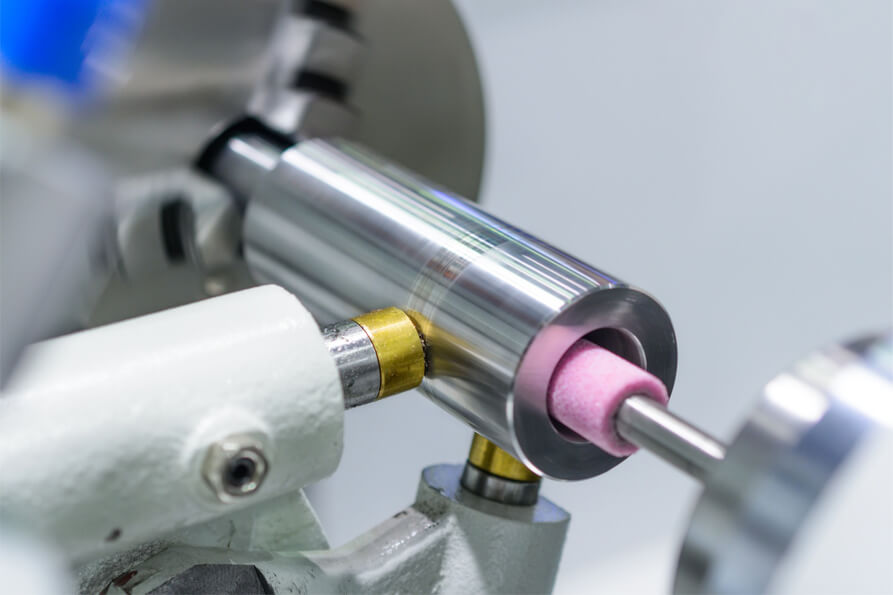

What is the strongest steel tube?

Strength is key when choosing the right steel tube.

The strongest steel tubes are made from high-grade carbon or alloy steel and are often seamless for durability Strongest types of steel tubes[^3].

Dive Deeper: Comparing Strength in Steel Tubes

The strength of a steel tube depends on its composition, wall thickness, and manufacturing method.

Strongest Steel Types

| Material | Strength Feature |

|---|---|

| Carbon Steel | High tensile strength |

| Alloy Steel | Enhanced by chromium or nickel |

| Stainless Steel | Combines strength with corrosion resistance |

Learn why seamless steel tubes are stronger[^4] for high-stress applications.

What’s the difference between steel pipe and steel tube?

Understanding the difference helps in making the right choice.

Steel pipes are measured by internal diameter for fluid transport, while steel tubes are measured by outer diameter for structural applications Steel pipe vs. steel tube[^5].

Dive Deeper: Pipes vs. Tubes

While both pipes and tubes are made from steel, they serve different purposes.

Key Differences

| Feature | Steel Pipe | Steel Tube |

|---|---|---|

| Measurement | Internal diameter (ID) | Outer diameter (OD) |

| Purpose | Fluid transport | Structural or mechanical uses |

| Precision | Less critical | Highly precise |

Understand the difference between pipes and tubes[^6] for your next project.

Why is steel tube so expensive?

The cost reflects the quality and manufacturing processes involved.

Steel tubes are expensive due to high-quality materials, specialized manufacturing processes, and strict quality standards Why steel tubes cost more[^7].

Dive Deeper: Factors Influencing Cost

Several factors contribute to the higher cost of steel tubes:

- Material Quality: Premium steel grades such as stainless or alloy steel.

- Manufacturing Method: Processes like ERW (Electric Resistance Welding) or seamless extrusion are costly.

- Precision and Standards: Adherence to strict tolerances and international standards.

Cost Breakdown

| Factor | Contribution to Cost |

|---|---|

| Raw Materials | High-grade steel |

| Manufacturing Process | Seamless or precision methods |

| Quality Testing | Ensures performance and safety |

Discover why steel tubes are expensive[^8] and if they’re worth the investment.

Conclusion

- Precision steel tubes offer unmatched accuracy and strength for machinery applications.

- Strongest tubes are seamless and made from high-quality materials like carbon or alloy steel.

- Steel tubes differ from pipes in precision and application, making them ideal for mechanical use.

- Manufacturing complexity and premium materials increase the cost of steel tubes.

Precision steel tubes are essential for industries requiring high-performance and reliable components.