Problem: Industries frequently struggle to find durable and precise tubing suitable for hydraulic systems and boilers.

Agitation: The use of inadequate materials can lead to system inefficiencies, frequent maintenance, and potential failures.

Solution: Seamless steel honing pipes and honed boiler tubes provide the necessary strength, precision, and reliability for demanding industrial applications.

Understanding Seamless Steel Honing Pipes and Honed Boiler Tubes

Seamless steel honing pipes and honed boiler tubes represent specialized steel tubing designed for high-pressure usage in hydraulic and thermal systems. The seamless construction ensures uniform strength, while the honing process creates a smooth internal surface, reducing friction and enhancing operational efficiency.

For more details on seamless steel tubes, visit [Skyline Pipes](). To learn about the honing process, refer to [Eastai Hydraulic]().

The Manufacturing Process of Honed Tubes

The production of honed tubes involves several critical steps:

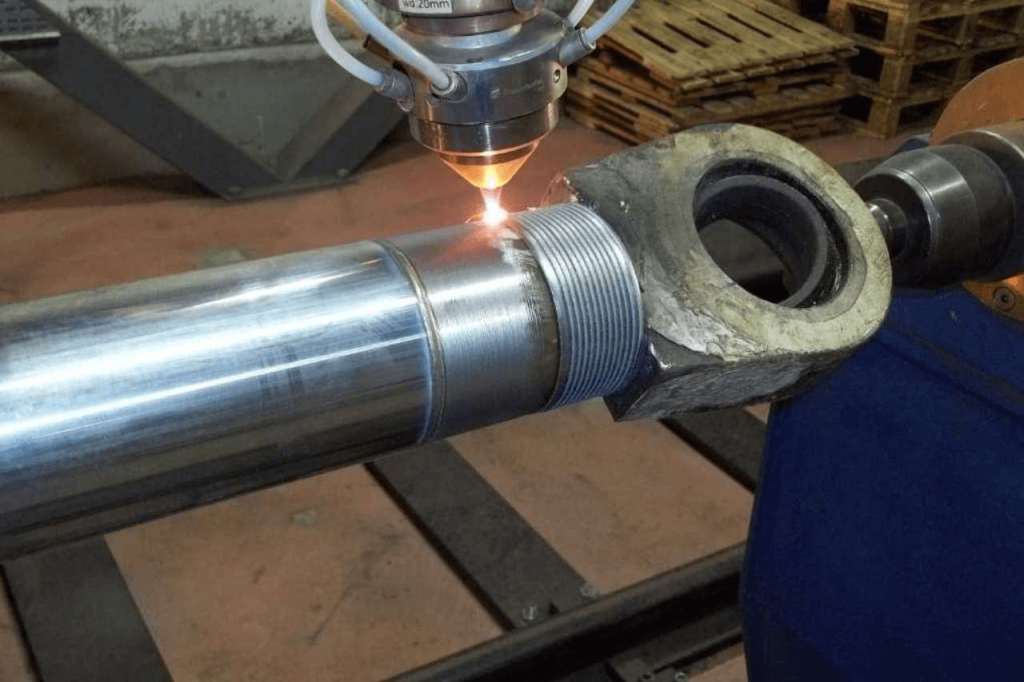

- Seamless Tube Formation: Using methods like cold drawing to produce tubes without welds, ensuring uniform strength.

- Honing Process: Employing deep hole tube honing machines to achieve precise internal diameters and smooth surfaces, essential for applications requiring minimal friction.

- Chrome Plating (for specific types): Applying a chrome layer to enhance corrosion resistance and durability, as seen in ST52 chrome plated honed tubes.

- Quality Inspection: Conducting rigorous tests to ensure the tubes meet industry standards and specific honed pipe specifications.

For a comprehensive view of the manufacturing process, refer to Skyline Pipes. To learn about the benefits of chrome plating, consult [Eastai Hydraulic]().

Applications Across Industries

These tubes are integral to various sectors:

- Construction Equipment: Honed tubes find application in hydraulic cylinders of machinery such as excavators and loaders.

- Industrial Machinery: The tubes are essential for systems requiring precision, such as injection molding machines.

- Automotive Industry: They are utilized in hydraulic jacks and braking systems.

- Energy Sector: Honed tubes are employed in boilers and heat exchangers, delivering durability and the capacity to withstand high temperatures and pressures.

For more on applications, visit [Eastai Hydraulic](). To explore their uses in construction equipment, visit Skyline Pipes.

| Parameter | Specifications |

|---|---|

| Material | ST52, 45#, Stainless Steel, Aluminium |

| Outer Diameter (OD) | 40 mm to 762 mm |

| Inner Diameter (ID) | 30 mm to 700 mm |

| Wall Thickness | 2 mm to 40 mm |

| Length | Up to 15 meters (customizable) |

| Surface Finish (Honing) | Roughness: RA 0.1 µm to RA 0.4 µm |

| Chrome Plating Thickness | 20 µm to 50 µm (for chrome plated tubes) |

| Tolerance | H7, H8, H9, as per application requirements |

| Standards | DIN2391, EN10305, ASTM A519 |

| Applications | Hydraulic cylinders, industrial boilers, construction equipment, and energy systems |

| Customizable Options | Length, diameter, wall thickness, surface finish, and material |

Advantages of Using Honed Seamless Stainless Steel Pipes in Hydraulic Systems

Problem: Hydraulic systems demand components that can endure high pressures and provide smooth operation.

Agitation: Inferior pipes can lead to leaks, inefficiencies, and system failures.

Solution: Honed seamless stainless steel pipes offer superior corrosion resistance, precision, and durability, ensuring optimal performance in hydraulic applications.

To understand the benefits of using stainless steel honed pipes, visit Skyline Pipes. For insights into the crucial role these pipes play in hydraulic systems, check [Eastai Hydraulic]().

How the Honing Process Enhances Surface Finish

Problem: Rough internal surfaces in pipes can cause friction and wear, reducing system efficiency.

Agitation: This leads to increased maintenance and operational costs.

Solution: The honing process uses abrasive tools to smooth the internal surface, resulting in a mirror-like finish that minimizes friction and wear.

For a detailed explanation of the honing process, visit [Eastai Hydraulic](). To see its impact on surface finish, refer to Skyline Pipes.

Common Industries Utilizing Honed Seamless Steel Pipes

Problem: Various industries require reliable tubing solutions for critical applications.

Agitation: Selecting inappropriate materials can compromise safety and efficiency.

Solution: Honed seamless steel pipes are favored in industries such as construction, manufacturing, automotive, and energy for their strength and precision.

For industry-specific applications, see Skyline Pipes. To explore their use in manufacturing, check [Eastai Hydraulic]().

Maintenance Requirements for Honed Seamless Steel Pipes

Problem: Even high-quality pipes require proper maintenance to ensure longevity.

Agitation: Neglect can lead to premature wear and system failures.

Solution: Regular inspections, cleaning, and adherence to operational guidelines are essential to maintain the integrity of honed seamless steel pipes.

For maintenance tips, visit [Eastai Hydraulic](). To understand common issues and solutions, refer to Skyline Pipes.

Dimensional Variations for Different Applications

Problem: Applications have specific dimensional requirements for tubing.

Agitation: Using incorrect sizes can lead to inefficiencies and potential failures.

Solution: Honed seamless steel pipes are available in various sizes and can be customized to meet precise application needs, including cold drawn pipe honed tubes and precision carbon honed seamless steel pipes.

For information on available sizes, see Skyline Pipes. To explore customization options, check [Eastai Hydraulic]().

Conclusion

Seamless steel honing pipes and honed boiler tubes are indispensable in modern engineering, offering unparalleled strength, precision, and reliability. Their applications span multiple industries, ensuring efficiency and safety in critical systems. Understanding their manufacturing process, applications, and maintenance requirements is essential for optimizing their use in various engineering fields.

For further reading, visit Skyline Pipes and Eastai Hydraulic.